Technology that gets you moving

Pneumatic Conveying Guide

Elevate Your Material Handling with Our Advanced Pneumatic Conveying Solutions

Pneumatic conveying is an efficient and cost-effective method for transporting dry bulk materials such as powders and granules. This technology offers significant advantages in terms of energy consumption and operational efficiency, making it ideal for a wide variety of industrial applications. Pneumatic conveying operates on the principle of using air pressure (positive or negative) to move bulk materials through a pipeline.

Typical Applications

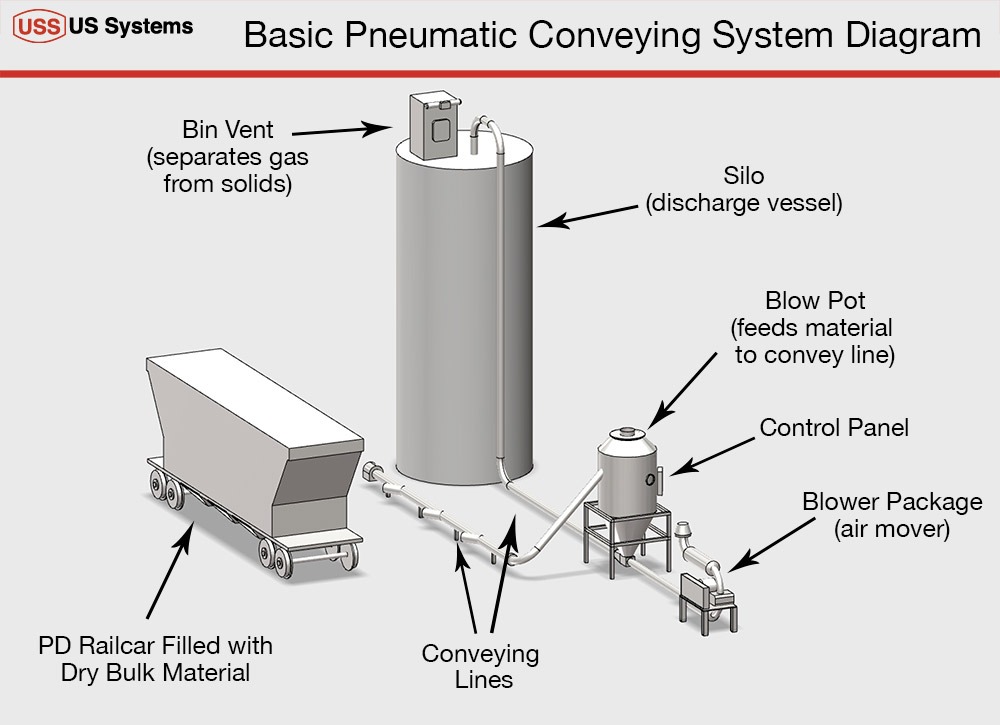

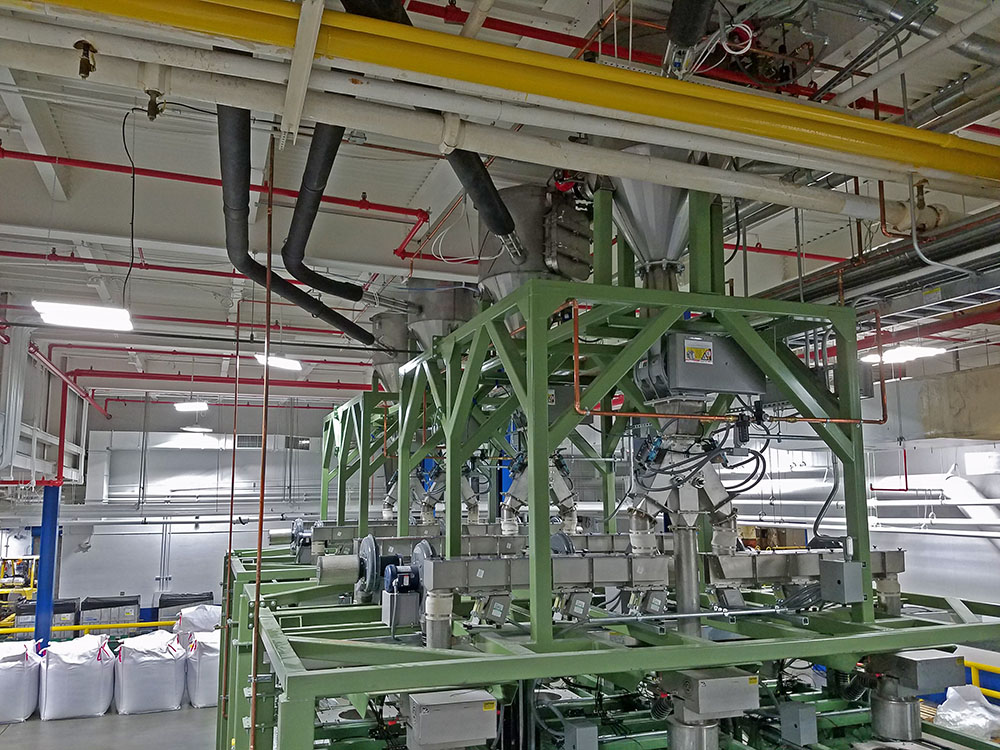

A typical pneumatic conveying system we design and manufacture involves transporting materials such as polymers, lime, soda ash, plastic pellets, and dry milk from a railcar or truck to a silo, or vice versa, using sealed pipes or tubes. Additional applications include intermodal/transloading, in-plant transfers, dust control, and portable solutions.

System Components

It’s crucial to understand that a “pneumatic conveyor” is not a single component but a sophisticated assembly of multiple components working in harmony. Here are the essential parts of a pneumatic conveying system:

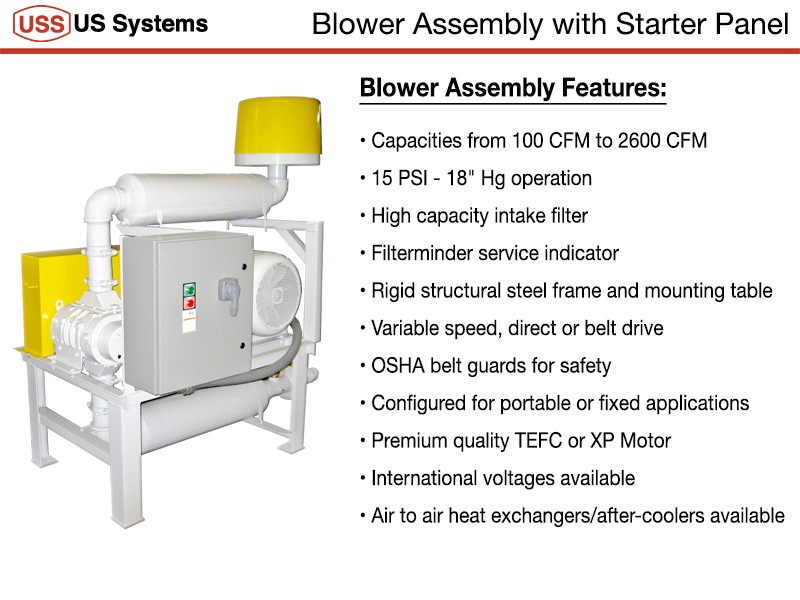

- Positive Displacement Blower: Provides the necessary air pressure or vacuum to move the materials. The selection of the PD blower depends on the system type, material characteristics, and conveying distance.

- Feed System: The feed system introduces the material into the conveying line and can include equipment such as flap valves or rotary valves. The choice of feed system depends on the material’s properties and the conveying application.

- Conveying Line: Typically made of metal, the conveying line transports the material from the source to the destination. The line design must account for factors such as material type, conveying velocity, and pressure drop.

- Elbows and Bends: Used to change the direction of the conveying line. Specially designed elbows and bends minimize wear and pressure drop, ensuring smooth material flow.

- Air Filtration System: Filters the exhausted air to remove any remaining dust or particles, ensuring that only clean air is released or recirculated. Often a reverse-pulse jet type for online cleaning of filter cartridges or bags.

Operation Phases

- Material Entry: The material is introduced into the conveying line through the feed system.

- Conveying: The air stream generated by the blower or compressor moves the material through the pipeline. The material can travel in a dense phase (high material-to-air ratio) or dilute phase (low material-to-air ratio) depending on the system design.

- Material Separation: At the destination, the material is separated from the air stream using a filter or cyclone separator.

- Exhaust Filtration and Material Separation: Material is separated from the air stream using filtration or separation to remove any particles before exhausting the atmosphere.

Typical Applications

- Food Industry: Used to transport materials such as flour, grain, milk powder, seeds, and sugar while maintaining hygiene and preventing contamination.

- Pharmaceutical Industry: Essential for transporting fine powders and granules in a clean and controlled environment.

- Chemical Industry: Used to convey chemicals like lime, soda ash, cement, alumina, talc, and silica with minimal risk of contamination.

- Mining and Minerals: Ideal for transporting raw materials and finished products, including ores and minerals.

- Cement and Construction: Utilized for conveying cement, fly ash, and other construction materials efficiently.

- Agriculture: Employed for moving grains, feed, and other agricultural products.

This diagram shows the basic components of a pneumatic conveying system. In this particular system the operator connects the intake convey lines to the PD railcar and after a safety check, starts the system.

- The blower motor starts and then turns the shaft of the blower via belts or direct drive. The blower intakes filtered air, compresses it, and then pushes it through the line.

- The pot then utilizes a USS Venturi or DirectAir Valve to induce a vacuum and the material is vacuumed from the railcar into the Pot. Some systems may employ two blowers (pressure and vacuum) instead of one blower and a venturi system.

- Either by sensor automation or by manual control, the system will switch from vacuum to pressure mode and the material is blown through the sealed convey lines and into the silo where a filter will separate the gas from the material.

- This cycling process continues at high rates until the car is empty.

Advanced Controls

The control panel is the ‘brains’ of the system, initiating the blower, receiving sensor data, and timing equipment operations to achieve optimal rates. While typically powered by electricity, we also offer pneumatic logic controls for situations where electricity is unavailable or undesirable. For more complex installations, Programmable Logic Controllers (PLCs) are employed.

Our team of skilled automation engineers ensures that every control system is meticulously crafted to offer full control over every aspect of the pneumatic conveying process. This comprehensive approach ensures maximum efficiency, reliability, and ease of operation.

Pneumatic conveying is a sophisticated and efficient method for transporting bulk materials through pipelines using air. Its flexibility, cleanliness, and ability to handle various materials make it an attractive choice for many industries. The system’s design and operation must be tailored to the specific material characteristics and application requirements to ensure optimal performance and efficiency.

Discover how our advanced pneumatic conveying solutions can revolutionize your material handling processes by providing unmatched efficiency and reliability. Contact us to learn more about our customized systems and how they can benefit your operations.

Why Pneumatic Conveying is a Superior Solution

Pneumatic conveying offers a deceptively simple yet highly effective solution to many traditional conveying problems. It serves as an elegant alternative to mechanical conveyors, which often rely on hard-to-maintain moving parts such as belts, screws, rollers, vibrating plates, elevator buckets, drag chains, cables, and discs.

Benefits of Pneumatic Conveying

- Flexibility:

- Versatile Layouts: Pneumatic conveying systems can be easily adapted to fit around obstacles and existing equipment in a plant. This flexibility allows for a more efficient and customizable design compared to more rigid mechanical systems.

- Long Distances: These systems are capable of transporting materials over long distances without significant loss or degradation. This is particularly beneficial in large industrial settings where materials need to be moved across vast areas.

- Cleanliness and Hygiene:

- Enclosed System: The enclosed nature of pneumatic conveying helps prevent contamination and exposure to dust, maintaining a clean and safe working environment. This is crucial in industries where hygiene is paramount, such as food processing and pharmaceuticals.

- Hygienic Handling: The system is particularly suited for materials that require strict hygiene standards, ensuring that transported materials remain free from contamination.

- Reduced Material Degradation:

- Gentle Handling: Pneumatic conveying provides a gentle method of transporting materials, which minimizes damage to fragile items. This is essential for maintaining the quality and integrity of sensitive materials during transport.

- Efficiency and Control:

- Consistent Flow: Pneumatic systems offer a consistent and controllable flow of materials, which improves overall process efficiency. This ensures that materials are delivered at a steady rate, enhancing productivity.

- Automated Control: These systems can be easily integrated with automated control systems, providing precise material handling and reducing the need for manual intervention.

- Safety:

- Minimized Dust Explosion Risk: The enclosed design of pneumatic conveying systems helps reduce the risk of dust explosions, thereby enhancing workplace safety. This is particularly important in industries that handle fine, combustible materials.

- Reduced Manual Handling: By automating the material transport process, these systems decrease the need for manual handling, reducing the risk of worker injury and enhancing overall safety.

- Space-Saving:

- Compact System: Pneumatic conveying systems are generally more compact and require less floor space compared to mechanical conveying systems like belt or screw conveyors. This makes them ideal for facilities where space is at a premium.

- Versatility of Materials:

- Wide Range of Materials: These systems are suitable for conveying a variety of materials, including powders, granules, pellets, and even some liquids. This versatility makes them highly valuable across different industries.

- Energy Efficiency:

- Optimized for Specific Applications: When designed and implemented correctly, pneumatic conveying systems can be energy-efficient and cost-effective. They can be tailored to specific applications to ensure optimal performance.

- Ease of Maintenance:

- Fewer Moving Parts: Pneumatic conveying systems typically have fewer moving parts than mechanical conveyors. This leads to reduced maintenance requirements and less downtime, contributing to overall operational efficiency.

- Efficiency with Fine Materials:

- Fine Material Handling: Pneumatic conveyors excel at transporting small and fine materials, including plastic pellets and powders, polymers, lime, soda ash, cement, alumina, talc, and silica. Unlike mechanical systems, which may struggle with these materials and face issues like grinding or clogging, pneumatic systems handle them with ease.

- Ideal for Food Products:

- Food Handling: These systems are particularly well-suited for handling food items such as flour, grain, milk powder, seeds, and sugar. In a pneumatic system, these materials remain intact and uncontaminated, unlike in mechanical systems where they can be ground down or get stuck between components.

- Enclosed System for Contamination Control:

- Contamination Control: One of the key advantages of pneumatic conveying is its fully enclosed system. This design prevents materials from being scattered, spilled, ground up, or undesirably dispersed outside the conveying system. As a result, it ensures clean, efficient, and contamination-free transport of materials.

By suspending particles in air and moving them through a sealed system, pneumatic conveying provides an efficient and reliable solution to many of the challenges faced by traditional mechanical conveyors. This makes it an excellent choice for a wide range of applications, ensuring the safe and effective transport of various materials.

One Size Does Not Fit All: The Benefits of Customized Solutions

At US Systems, our motto, “Total System Responsibility,” reflects our commitment to understanding your needs and designing customized solutions that address your unique challenges.

The Pitfalls of Pre-Fab Systems

Pre-fabricated systems forced into custom applications often lead to disruptions and issues once installed. These problems may not become apparent until months later, resulting in costly fixes that could have been avoided through a careful evaluation of your specific material handling needs.

The Value of Custom Solutions

Opting for a custom solution doesn’t necessarily mean higher costs. In fact, a tailored system often works more efficiently and with fewer problems. Pneumatic conveying should alleviate headaches, not create new ones.

Our Commitment to You

At US Systems, we go the extra mile to carefully analyze your needs. Our team works diligently to design customized solutions that save you time, effort, and money, all while providing a hassle-free experience. Plus, our custom solutions are competitively priced against pre-fabricated options.

For efficient, reliable, and cost-effective pneumatic conveying systems, trust US Systems to deliver solutions that fit your specific requirements.

Understanding Rotary “Airlock” Valves: Pros, Cons, and Alternatives

Rotary airlock valves are frequently the right component for feeding material in many applications—but not always. While they play a critical role in metering material and separating pressure/vacuum zones, they come with inherent issues and are often expensive and require regular maintenance.

The Imperfect Airlock

Rotary valves are often used as “airlock” valves, but they don’t perfectly seal the air between pressure and vacuum zones. This imperfection leads to “blowby air,” which flows across the pressure differential, causing pressure loss, other operational issues, and unplanned downtime.

Challenges with Blowby Air

Blowby air can cause material bridging in the bin above, resulting in no-flow situations. Over time, as the vanes wear down due to material entrainment, air leakage through blade tip clearances increases. This can generate high-velocity flows that entrain fine particles, leading to severe erosive wear compared to abrasive wear. Eventually, excessive pressure drops can cause system plugs.

Maintenance and Longevity Issues

Rotary airlock valves are subject to wear and tear, plain and simple. Often, you will need two airlock valves to ensure one can be in use while the other undergoes repair. Sales and repair of rotary valves constitute a significant portion of revenue for many large pneumatic conveying companies. However, not every system requires a rotary valve.

Alternative Solutions

At US Systems, we often engineer solutions that eliminate the need for a rotary valve. By understanding the specific needs of our customers, we can recommend simpler and more cost-effective alternatives, such as our cycling loader or cycling “Pot” system. These systems are automatic and achieve high rates without the complications and costs of an airlock. In many applications, simple passive flap valves or butterfly valves can do the job at cost savings that pay off for years into the future.

Benefits of Our Cycling Pneumatic Conveyor

Our cycling pneumatic conveyor system addresses common issues associated with rotary airlock valves, including:

- Blowby Air

- Worn Shaft Seals and Packing

- Bent Rotors

- Worn and Chipped Rotors

- Wasted Horsepower and Energy

- Worn-Out Housings

- Chain Drive Maintenance

- Inherent Leaks

Expertise and Custom Solutions

It’s essential to work with a conveying company experienced in handling your specific material’s flow characteristics. US Systems takes into account the unique circumstances of each application and the associated costs when utilizing or recommending alternatives to rotary valves.

For the best performance and cost-efficiency, consider our innovative solutions designed to optimize your material handling processes.

How We Control Excessive Fines and Protect Friable Material

Excessive fines can occur in pneumatic conveying systems due to various reasons. Pellets may stick to the walls, leaving behind material known as angel hair, which eventually breaks off and contaminates the system. This material can also form a coating inside the pipe that peels off, referred to as snakeskin. Additionally, pellets might have small imperfections after cutting, such as an ‘ear’ sticking out, which breaks off and creates fines. These fines can affect the melting process of pellets and lead to defects.

Causes and Mitigation Strategies

The causes of fines vary depending on the application, but there are several strategies to mitigate this phenomenon. Here are some key methods:

- Material Coating and Treatment: Applying specialized coatings to the interior surfaces of pipes can reduce the adhesion of pellets and minimize the formation of angel hair and snakeskin.

- Optimized Cutting Techniques: Using advanced cutting techniques can reduce the imperfections on pellets, minimizing the creation of fines.

- Flow Rate Management: Controlling the flow rate of materials through the system can help prevent excessive friction and adhesion.

- Proper System Design: Ensuring that the pneumatic conveying system is designed with the specific material characteristics in mind can help mitigate the production of fines.

- Regular Maintenance: Implementing a routine maintenance schedule can help identify and address issues before they lead to significant fines.

It’s crucial to work with a pneumatic conveying company experienced in handling these specific problems to ensure the best performance and minimal issues with fines. US Systems brings extensive expertise in designing and maintaining systems that address and mitigate the causes of excessive fines, ensuring efficient and defect-free material handling.

Ensuring Reliable Material Conveying: Our Expertise and Solutions

At US Systems, we leverage our extensive experience and expertise to address and prevent common challenges in material conveying. Here are some typical issues and our strategies to mitigate them:

Preventing De-mixing of Mixtures

When one ingredient absorbs moisture from the air and sticks to the wall, the remainder of the mixture might flow through the line improperly. Our systems are designed to manage moisture and ensure even flow, preventing de-mixing.

Managing Powdery Mixtures

A dry, powdery mixture that pours readily out of a container may become a pasty mass in the conveying line due to the conveying air absorbing heat from the air blower. We can implement temperature control measures to maintain optimal conditions for smooth conveying.

Handling Abrasive Materials

An abrasive material that is successfully conveyed without erosion can suddenly cause excessive wear if the material’s source or pulverizing method changes. We utilize durable, wear-resistant materials and adaptable system designs to handle such variations. Additionally, we provide solutions such as ceramic-backed elbows and other ceramic or polyurethane components to save customers time and money. With industrial controls experts on staff, we can also use automated control systems to monitor and adjust the flow rate in real time.

Protecting Friable Materials

Friable materials can degrade when air-conveyed through pipelines with several bends. Our engineering solutions include designing gentle conveying paths that minimize bends and reduce the risk of material degradation.

Pipeline Blockages (Plugging and Choking)

Pipeline blockages are another common issue that can halt operations and require time-consuming maintenance. Proper line sizing is crucial to ensure the pipeline diameter is appropriate for the material being conveyed and the required flow rate. Flow aids such as air blasters or vibrators can also be employed to keep the material moving and prevent clogs.

Dust Control

Dust generation and air quality are significant concerns in pneumatic conveying. Dust can pose health risks and reduce air quality. Ensuring the conveying system is fully enclosed helps prevent dust from escaping. Installing dust collection and air filtration systems can capture airborne particles, maintaining a clean and safe environment.

Controlling Heat

In pneumatic conveying systems, the blower or compressor generates heat as a byproduct of pressurizing the air used for transporting materials (adiabatic compression). This heat can negatively affect some materials, especially those sensitive to temperature changes. Elevated temperatures can cause materials to degrade, become sticky, or change their physical properties, potentially leading to blockages, reduced product quality, and operational inefficiencies. For instance, sugar is sensitive to high heat so we often employ an aftercooler on pressure systems. An aftercooler, positioned downstream of the blower, effectively mitigates these effects by cooling the pressurized air before it enters the conveying line. The aftercooler uses a heat exchanger to transfer the excess heat from the air to a cooling medium, such as water or ambient air, reducing the air temperature to an acceptable level. This cooling process ensures that the conveyed materials remain stable and maintain their desired properties throughout the transport process, thereby enhancing the reliability and efficiency of the pneumatic conveying system.

Only through careful design and engineering can we preserve the properties and characteristics of the material handled.

Understanding Material Characteristics in Pneumatic Conveying

Pneumatic conveying systems are highly versatile and can handle virtually all powder and granule materials. However, the characteristics of the material being conveyed are crucial in ensuring the system is tuned correctly to the application. This fine-tuning allows for high efficiency and all the benefits associated with pneumatic conveying.

Key Material Characteristics:

- Specific Gravity: Determines the weight of the material relative to the volume.

- Aerated or Loose Specific Weight: The weight of the material when aerated or in a loose state.

- Settled Specific Weight: The weight of the material when settled and compacted.

- Particle Size: Impacts the flowability and behavior of the material during conveying.

- Abrasiveness: Refers to the potential of the material to cause wear and tear on the conveying equipment.

- Moisture Content: Affects the flow characteristics and potential for clumping.

- Corrosiveness: Indicates the material’s potential to cause corrosion in the conveying system.

- Tackiness: Refers to the stickiness of the material, which can affect flow and adhesion to surfaces.

- Aeration and De-Aeration Characteristics: The material’s ability to incorporate and release air.

- Angle of Repose: The steepest angle at which the material remains stable without sliding.

- Toxicity: The potential health hazards associated with the material.

- Temperature Limitations: The acceptable temperature range for handling the material without degradation.

- Crystal Structure, Form of Particles: The physical structure and form of the material particles.

- Absorption of Odors: The material’s ability to absorb and retain odors.

Ideal Materials for Pneumatic Conveying:

The best materials for pneumatic conveying are typically:

- Free-flowing

- Non-abrasive

- Non-fibrous

By carefully considering these material characteristics, US Systems can design a pneumatic conveying system that is optimized for your specific needs. This ensures efficient, reliable, and cost-effective operation.

General Pneumatic Conveying System Types:

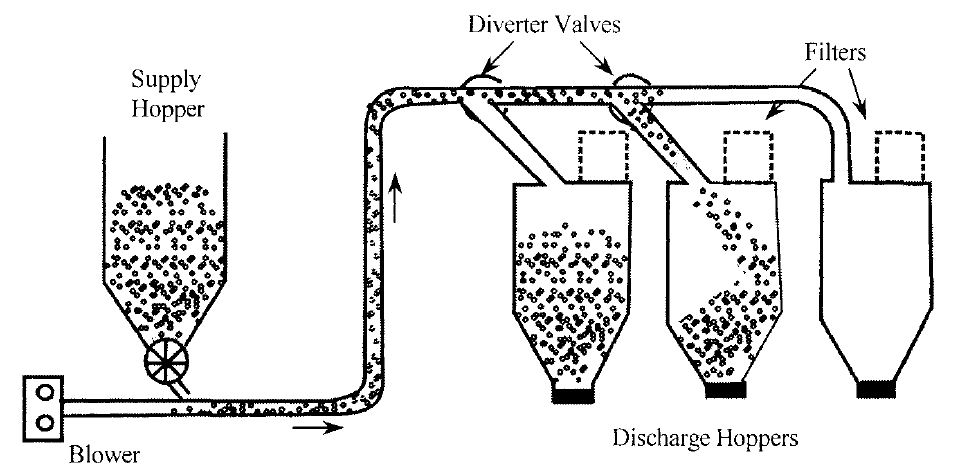

Positive Pressure

Blows material from a single source to one or multiple destinations. Generally offers higher efficiency over vacuum systems.

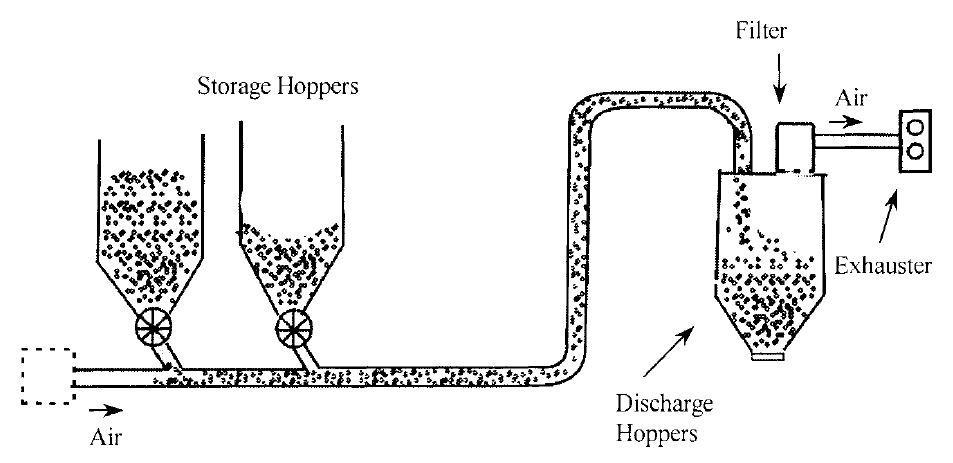

Negative Pressure

Sucks material from one or multiple sources to a destination. Doesn’t impart heat into the system. Allows for material pickup from a wand.

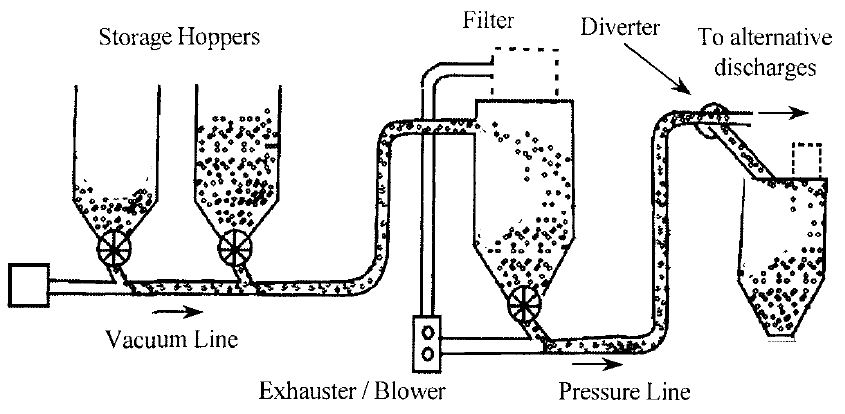

Combination Vacuum/Pressure Systems

Blows and sucks the material at the same time. Often utilizes two blowers – one each for the vacuum and pressure zones of the system. Utilizes a rotary airlock valve to separate the vacuum and pressure sides of the system.

Understanding Phases in Pneumatic Conveying Systems

Pneumatic conveying systems can operate under different phases, each defined by the way materials and air flow through the system. Let’s delve into what these phases entail:

Single-Phase Flow

Single-Phase Flow involves a single, homogeneous material moving through the system. In the context of pneumatic conveying, this typically refers to air-only flow.

Multi-Phase Flow

Multi-Phase Flow occurs when more than one material flows through the system. In pneumatic conveying, this means both air and the conveyed material are moving together. Multi-Phase Flow is further characterized by the “solids loading ratio,” which is the air-to-material ratio. These are also known as “flow regimes.”

Flow Regimes: Dilute Phase vs. Dense Phase

Dilute Phase Systems

Dilute Phase systems have a higher air-to-material ratio. These systems usually operate with air at higher velocities and lower pressures. The air moves fast enough to carry the material through the system to its destination. About 90% of pneumatic conveying applications fall under the dilute phase category.

Dense Phase Systems

Dense Phase systems have a lower air-to-material ratio. They typically run at lower air velocities and higher pressures. The conveyed material must be highly uniform and capable of aeration, as it will move through the system in dunes or plugs. Dense Phase systems are more expensive, must be extensively tested before the system is designed, and represent roughly 10% of the pneumatic conveying market.

Key Considerations

There isn’t a universally agreed-upon point at which a dilute-phase system transitions to a dense-phase system. This depends on factors such as bulk density and the specific characteristics of the material and system in use. Generally, dense-phase systems require higher pressures and high-pressure-rated vessels.

Automation

Our systems feature industrial-duty NEMA-rated control panels that significantly enhance the automation of your processes. These advanced control panels ensure that your system operates smoothly with minimal downtime, thereby improving overall efficiency and productivity.

Key Features of Our Control Panels:

- NEMA-Rated Panels:

- Designed to meet rigorous standards, these panels provide superior protection and reliability, ensuring long-lasting performance in harsh industrial environments.

- Disconnect Switch:

- Facilitates the safe disconnection of electrical power to your system, allowing for maintenance and emergency shutdowns without compromising safety.

- Primary Circuit Protection:

- Protects your system from electrical faults and overloads, minimizing the risk of damage and maintaining operational continuity.

- Industrial-Duty Buttons, Selector Switches, and Door Devices:

- Robust and durable components that offer reliable control and easy operation, designed to withstand heavy usage in demanding industrial settings.

- PLC – Programmable Logic Controller:

- Provides advanced automation capabilities, enabling precise control over various processes and functions within your system. The PLC can be programmed to execute complex tasks and ensure efficient operation.

- Motor Starters:

- Ensure the smooth starting and stopping of motors, reducing mechanical stress and prolonging the lifespan of your equipment.

- HMI – Human Machine Interface:

- Offers an intuitive and user-friendly interface for operators to monitor and control the system. The HMI displays real-time data and allows for easy adjustments to optimize performance.

- LED Indicator Lights:

- Provide visual status updates, allowing for quick identification of system conditions and enhancing operational awareness.

- Variable-Speed Controls:

- Enable precise regulation of motor speeds, optimizing energy consumption and improving process control.

- Touchscreen:

- A responsive and interactive display that simplifies system management, offering easy access to settings, controls, and diagnostic information.

- Remote Networking Capability:

- Allows for remote monitoring and control of your system, enabling timely interventions and adjustments from any location, improving responsiveness and flexibility.

- Data Collection:

- Facilitates the gathering and analysis of operational data, providing insights into system performance and helping identify areas for improvement. This feature supports predictive maintenance and process optimization.

Quality Counts

At US Systems, we understand the demanding environments in which our customers operate. Therefore, our pneumatic conveying equipment, including pots, boosters, and supporting systems, are engineered to be exceptionally rugged and reliable.

Robust Construction and Design

Each US Systems Pot is built with durable materials such as stainless steel, aluminum, or carbon steel, ensuring long-lasting performance even in the harshest conditions. This construction choice not only provides strength but also resistance to corrosion, wear, and other environmental factors.

Visual Inspection and Easy Maintenance

Our pots are equipped with visual inspection sight glasses, allowing operators to monitor the material flow and system performance without interrupting operations. User-friendly access and clean-out ports facilitate easy maintenance and cleaning, ensuring minimal downtime and maximum efficiency.

Advanced Control Options

We offer both manual and automatic control options for pneumatic and electrical functions. This flexibility allows customers to choose the control method that best suits their operational needs. Our control panels can include features such as:

- 12VDC, Pneumatic, or 120VAC Options for Controls: These options ensure compatibility with various power systems and operational requirements.

- Premium Components: All components are selected for their durability and reliability, designed to withstand rigorous industrial use.

Premium Components for Longevity

We use only the highest quality components in our systems to ensure they stand the test of time. This commitment to quality means fewer breakdowns and longer intervals between maintenance, providing customers with a dependable solution for their pneumatic conveying needs.

By incorporating these robust features, US Systems ensures that our supporting systems not only meet but exceed the demands of your operations. Whether you’re dealing with abrasive materials, high throughput requirements, or challenging environmental conditions, our equipment is designed to deliver reliable, efficient performance.

For more information or to discuss your specific needs, please feel free to contact us. Our team is ready to provide the support and solutions you need to optimize your material handling processes.

Commissioning and Education

Pneumatic conveying systems provide reliable service, consistent uptime, and significant savings on labor and energy costs—up to a quarter of the cost of mechanical systems. Our systems can transport materials where others can’t, offering a refined and efficient solution. Unlike competitors who might consider their job done once the system is shipped, we ensure our clients receive comprehensive commissioning services. This means your system is operational from the start, perfectly balanced, and your operators are fully trained to use it efficiently.

Support After Installation

At US Systems, our commitment to you extends far beyond the installation phase. We offer a full range of consumables and replacement parts to keep your system running smoothly. With decades of experience, we’ve even refurbished 30-year-old USS machines and put them back into service. Ordering replacement parts, such as filters or fittings, is simple—just call 913-281-1010, and we’ll ensure you get what you need promptly.

For reliable, efficient, and well-supported pneumatic conveying solutions, US Systems is your trusted partner. Contact us to learn more about our comprehensive services and support.

Pneumatic Conveying Components & Accessories

At US Systems, we provide a comprehensive range of accessories designed to enhance the safety and efficiency of your operations. Our accessories are meticulously engineered to ensure seamless integration and optimal performance in your pneumatic conveying systems.

Camlock Fittings: Quick-connect couplings used to connect and disconnect hoses and pipelines securely and efficiently, often used in pneumatic conveying systems for their ease of use.

Compression Couplings: Couplings that use compression to join two pipes or tubes together, creating a strong and leak-proof seal without the need for welding or soldering.

Blow Thru Discharge Adapter: A component that allows materials to be discharged from a conveying system with the assistance of airflow, ensuring smooth and efficient transfer.

Railcar Hopper Adapter Pan: An attachment used to connect a railcar’s hopper to a conveying system, facilitating the unloading of bulk materials from the railcar.

Knife Gate Valves: Valves designed with a sharp-edged gate to cut through flowing materials, providing precise control over the flow in pneumatic conveying systems.

Butterfly Valves: Valves that use a rotating disc to regulate the flow of materials through a pipe, known for their quick operation and low-pressure drop.

Diverter Valves: Valves that redirect the flow of materials from one pipeline to another, used to control the routing of materials within a conveying system.

Railcar Boot-Lift: A device used to lift and position the boot of a railcar, enabling efficient connection to a pneumatic conveying system for unloading.

Industrial Filters: Filters used to remove contaminants and particulates from air or materials in a conveying system, ensuring clean and efficient operation.

Convey Line: The pipeline through which materials are transported in a pneumatic conveying system, designed to withstand the pressures and abrasiveness of conveyed materials.

Angel Hair Trap: A device used to capture and remove fine strands of material, known as “angel hair,” that can form during the conveying process, preventing blockages and maintaining system efficiency.

GP Railcar Outlet Adapter: An adapter that facilitates the connection between a general-purpose (GP) railcar outlet and a pneumatic conveying system, ensuring a secure and efficient transfer of materials.

Cyclone Separator: A device that uses centrifugal force to separate particulates from an air or gas stream, commonly used in pneumatic conveying systems to remove dust and debris.

Bins – Hoppers – Silos: Storage containers for bulk materials, designed to hold and release materials into a pneumatic conveying system as needed.

Blower Package: A self-contained unit that includes a blower, motor, and associated components, providing the necessary air flow and pressure for pneumatic conveying systems.

Bin Vent: A filter system installed on top of storage bins to allow air to escape while retaining the stored materials, preventing dust emissions and maintaining air quality.

Aftercooler: A device that cools the air discharged from a blower, reducing its temperature and moisture content before it enters the pneumatic conveying system, preventing material degradation.

Electrical Components: Various electrical parts used to control and monitor the operation of a pneumatic conveying system, including sensors, switches, and control panels.

Lump Breaker: A device used to crush or break down large lumps of material into smaller pieces, ensuring consistent material flow in a pneumatic conveying system.

Shot Box: A component used to collect and discharge material samples, allowing for quality control and analysis within a pneumatic conveying system.

Bin Vibrator: A device that uses vibrations to promote the flow of materials from storage bins, preventing blockages and ensuring consistent discharge.

Piston Vibrator for Bins and Silos: A specific type of vibrator that uses piston movement to generate vibrations, aiding in the flow of materials from bins and silos.

Rotary Valve Shear Protector: A safety device used to protect the rotary valve from shear forces, ensuring its reliable operation and longevity.

Rotary Valve: A valve that uses rotating blades to regulate the flow of materials, providing a consistent and controlled discharge in a pneumatic conveying system.

Sound Enclosures: Enclosures designed to reduce noise generated by pneumatic conveying equipment, creating a quieter working environment.

Ceramic-Backed Elbows: Elbows with a ceramic coating, used on pipeline bends to withstand abrasive materials and extend the lifespan of the conveying system.

PD Blowers: Positive displacement blowers that provide a steady air flow essential for maintaining pressure and airflow in pneumatic conveying systems.

PD Blower Oil: Specialized oil used to lubricate and maintain the performance of positive displacement blowers, ensuring their efficient and reliable operation.

CONVEY LINE ROUTING:

Poor:

- Sharp turns or elbows.

- Useless bends or turns.

- Shut-off or diverter valves in line.

- Longer line than necessary.

- Diagonal piping. Any deviation of 5 degrees or more from strictly horizontal or vertical will increase air requirement; otherwise surging plugging will result.

- Any leak in conveying line will have similar results to no. 5.

- Inadequate venting may result in pressure build-up in receiving tank and may cause it to bulge or rupture. Note: never use other fill pipe as venting.

- Fill pipe connection at bottom of the hopper. Unloading against static pressure of product in bin reduces unloading rate substantially.

- Horizontal hook-up connection to the hose.

- Reduction in pipe size. If a trailer or portable storage unit has 4″ or 5″ piping, 4″ or 5″ piping should be provided the full distance.

Good:

- Always short as possible.

- Keep the piping strictly vertical or horizontal when possible.

- Route the piping with as few bends as possible.

- All pipe bends should have four to five-foot radius turns (sweeps or 15 X diameter of pipe).

- Adequate venting on receiving bin.

- Adequate dust collector on receiving bin when necessary.

- Ample ground clearance (4-6ft.) at hose hook-up to allow liberal natural bend of hose.

- Tight and smooth joints.

- Use a 5″ or 6″ line when a high unloading rate is required – providing adequate CFM is available.

Your partner in process success

CONCEPT – DESIGN – ENGINEERING – FABRICATION – COMMISSIONING

Proudly serving the food, grain, coffee, plastics, mineral, chemical, and pharmaceutical industries

✓ System & Component Design

✓ Engineering

✓ Manufacturing

✓ Industrial Controls

✓ Installation & Commissioning

✓ Parts Support

For Product Inquiries:

Please describe the problem you’re looking to solve – a knowledgeable and experienced engineer is ready to help.