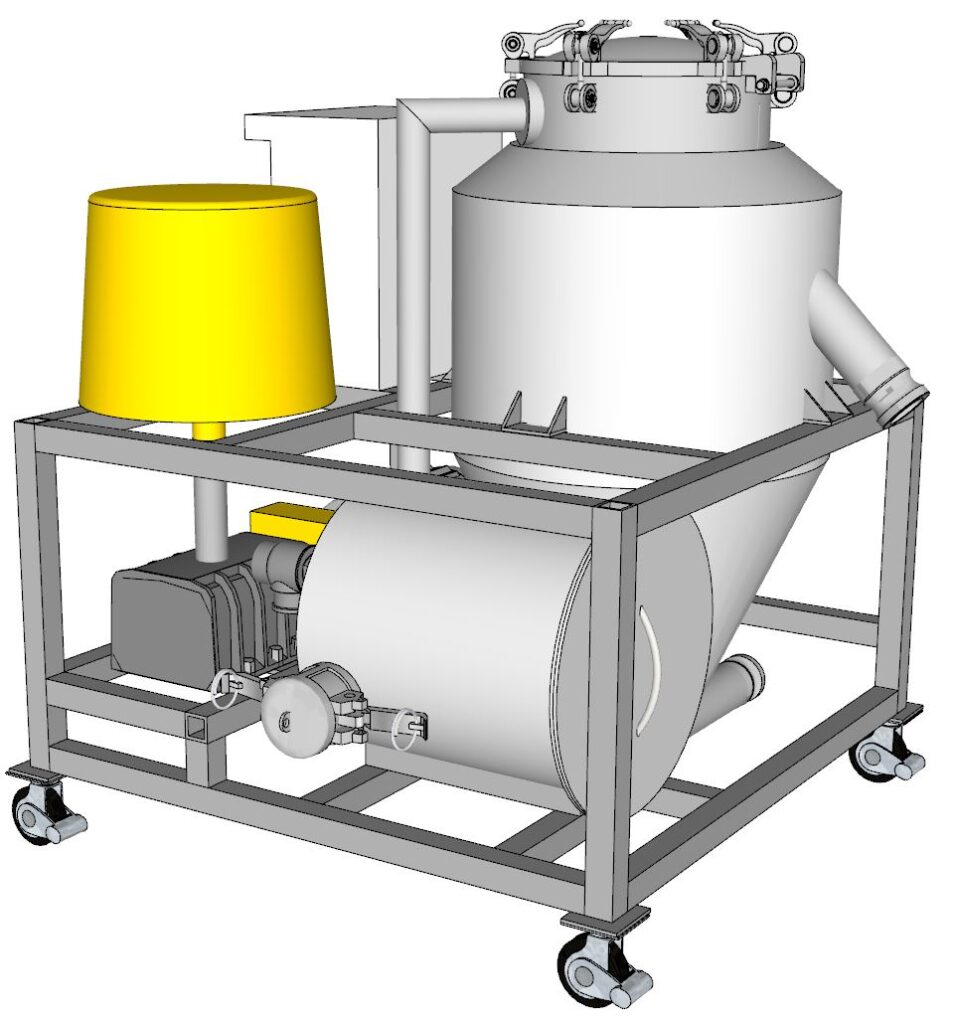

The Truly “Turn-Key” Pneumatic Conveyor

Saving Thousands on Installation and Maintenance Costs = Faster ROI

SAVE TONS OF MONEY WHILE CONVEYING TONS OF MATERIAL WITH A USS SKIDPOT™:

FEATURES AND OPTIONS:

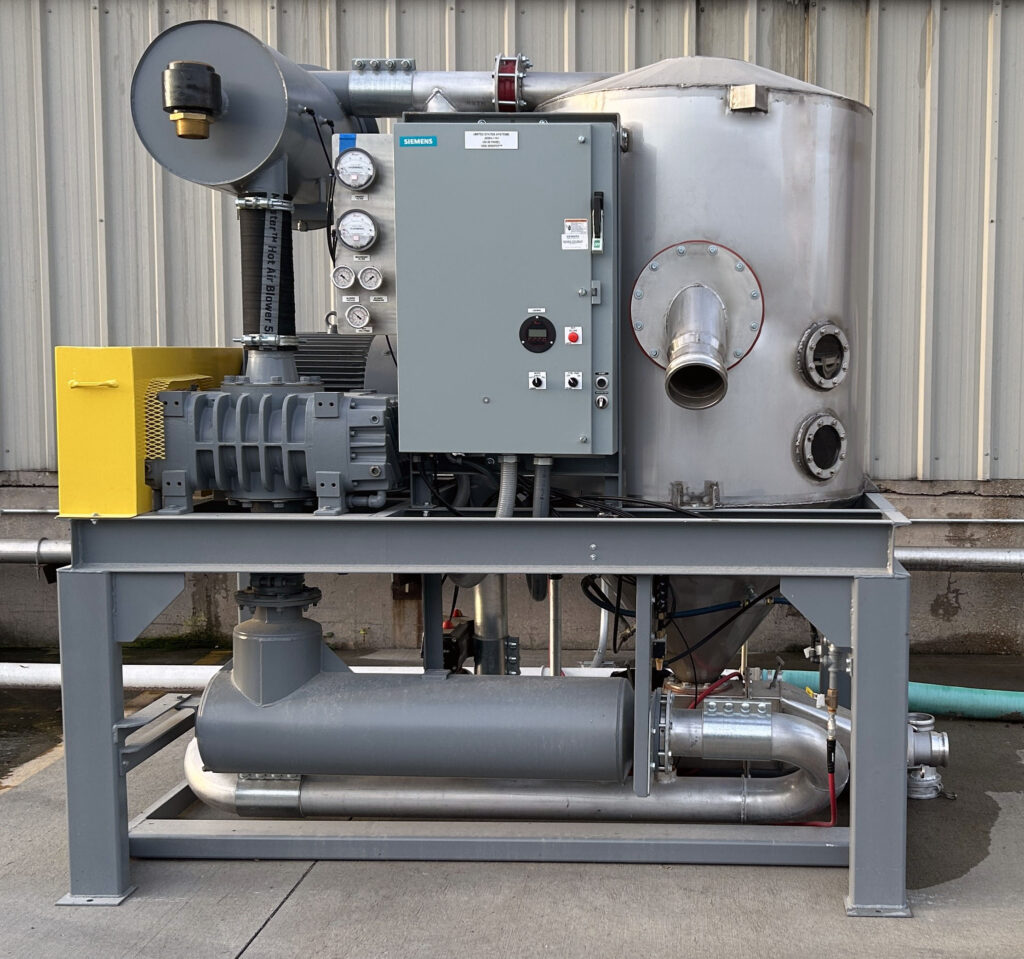

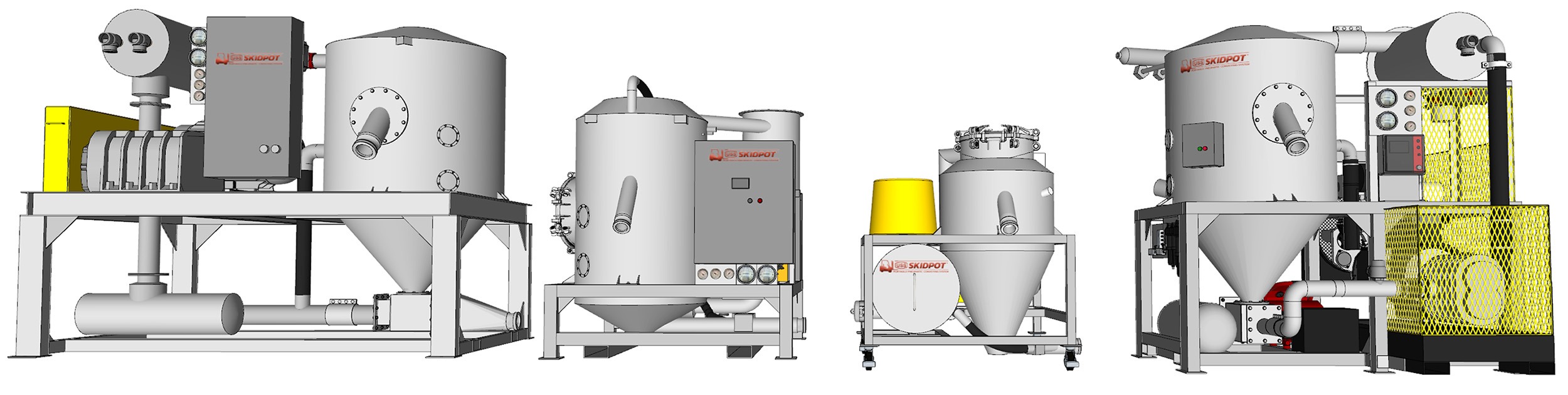

- All-in-One Skid-Mounted Portable Pneumatic Conveyor

- Motor and Motor Starter Panel

- Powerful blower to move material suspended in air

- V-Belt and DirectDrive options

- Forklift tine-slots for portability

- Pulse-Jet Filtration technology

- High filter air-to-cloth ratio

- Gauge dashboard

- Pressure/Vacuum Relief Valves for protection

- Easy tool-less access hatch

- Stainless product contact areas available

- Easy filter removal and replacement

- Available in a variety of sizes for any application

- Sturdy construction for stability and long blower life

- Easy product flow

- Flexible hoses available for inlet and discharge connections

- Diesel-engine driven option available for ultra-portability

- A dual-pot design allows for near-continuous conveying for even higher rates

BENEFITS:

- Custom-designed for your material

- Durable design for decades of use

- Expensive components are protected

- Product flows easily

- Safe and easy for operators to use

- Long-lasting industrial-duty components

- Can be used at one location or different sites

- Capital investment moves where you need it most

- Saving thousands on installation costs = Faster ROI

- Easy removal of filtration media

- Powerful enough to convey heavy powders

- Can be paired with a USS PORTA-BAGGER™

- Easy to ship

- Easy to install

- Easy to use

- Easy to move

- Easy to clean

- Easy to maintain

Pre-piped, pre-wired. Just add 90-100psi air and electrical.

No Air or Electricity? Compressor and Diesel options available.

View a 3D Model of the Diesel-Driven SkidPot™ HERE (give a minute to load)

Convey anywhere with an Ultra-Portable Diesel-Driven SkidPot™

Portable Pneumatic Conveying

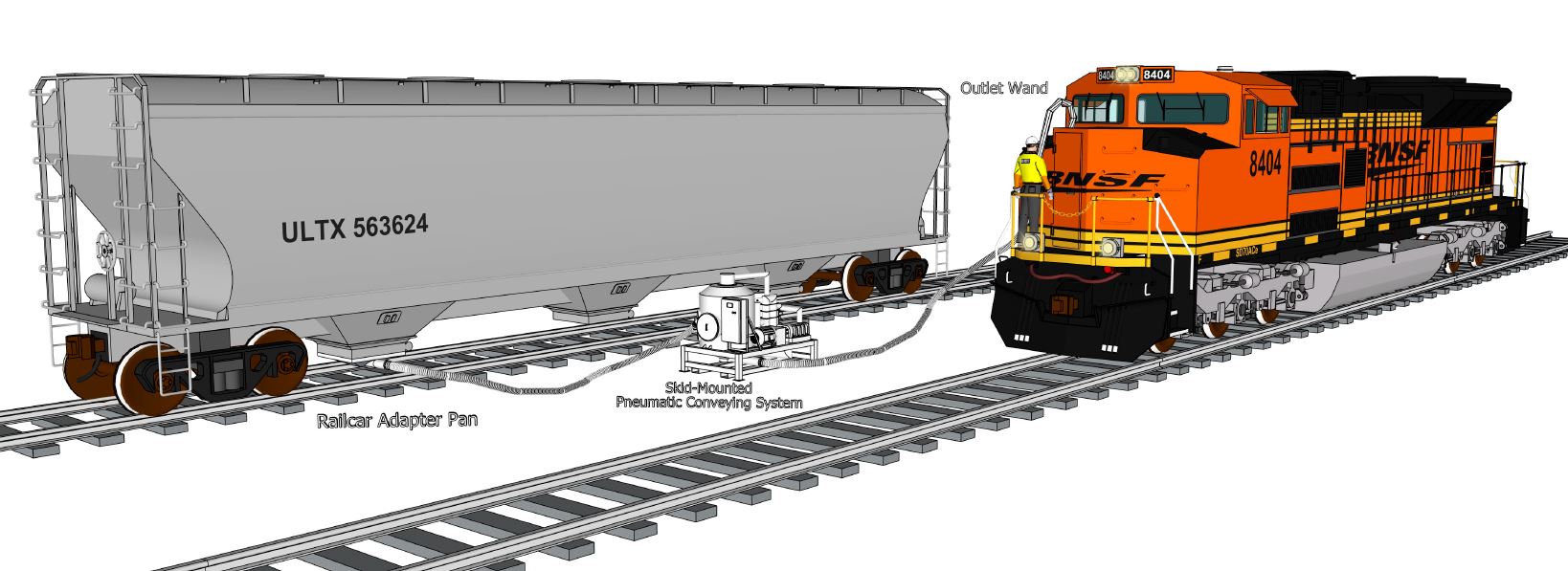

Railcar Unloading | Truck Unloading | Intermodal Transloading

Very Fast Rates – Easy Operation – Convey Anywhere

Conveying immense value in one easy-to-use portable package.

Pneumatic conveying is an elegant, efficient solution that allows us to engineer systems without excessive use of horsepower. We’ve taken that simplicity and elegance to a whole other level with our portable pneumatic conveying systems.

Our portable solutions allow for material transfer without moving railcars, which can be dangerous and time-consuming.

Instead of moving the railcar (or multiple railcars), an operator can unlock the industrial castors on our pneumatic conveying pot and move it to the next gate or car.

You can also transport the pot via forklift or truck to another location in the same plant or to another site altogether!

Being portable, they can be taken to any site where material needs to be conveyed, such as transloading between railcars and trucks.

Our unique design concept provides for limited maintenance and prevents premature wear on components. Savings in the use of horsepower translates into less system heat and product degradation.

There are many advantages to pneumatic railcar unloading compared to mechanical conveying. Less moving parts means less breakdowns, and an enclosed system means easy dust control. Another important advantage is flexibility in routing – we can convey material to places others can’t, and with our portable solutions, we can convey literally anywhere!

At it’s most basic, a pneumatic conveying system sucks dry bulk material through a tube from one location (railcar, truck trailer, silo, etc.) into a temporary ‘pot’, and then blows the material in a pipe towards it destination, usually another railcar, trailer, or vessel.

Our Portable Conveying Solution:

- Avoids moving railcars (for safety and cost).

- Easily move the equipment around.

- Used for multiple unloading positions.

- Can unload up to a four-car string.

- Can safely be moved by an operator on a paved surface.

- Can be used in multiple sites and locations.

- Saves capital outlay for short-term plant location.

- Can be shipped for unloading at different sites.

- Transloading from rail to truck can take place anywhere.

Portable Features:

- Foot, Caster, or Skid-Mounted Options

- NEMA-Rated Control Panel

- Forklift Tine Slots Optional

- Painted Carbon Steel, Stainless Steel, or Aluminum Construction

- Skid-Mounted Design Package Includes Blower Package

- 12VDC, Pneumatic, or 120VDC Options for Controls

- Manual or Automatic Controls of Pneumatic and Electrical Functions

High Rates

These high-rate systems employ either diesel or electric driven portable units that can range from 10 to 200 horsepower and can move material at a rate of one to one-hundred ton per hour.

Venturi-Based SkidPot™

Continuing customer requests for a portable, electric-powered, self-contained transfer unit for plant use have resulted in the Venturi-25 SkidPot™ pneumatic bulk transfer unit.

Shipped to your plant completely assembled, wired, and ready for service. It can be used anywhere your power cable can reach. No airlocks or butterfly valves to trap product means easy clean-up!

The Venturi-25 has an economical 15 PSI system, achieving high transfer rates without the need for expensive code vessels, compressors, and conveying lines.

Venturi-25 Features:

- All inside welds ground & polished

- Transport with forklift

- Available in aluminum and food grade, epoxy coated carbon steel

- Top loading model available for use under silos and storage hoppers

- Adaptable to any conveying line size

We Achieve High Rates with All Types of Railcars:

- Hopper

- Airslide

- Pressure Differential Cars

We Provide Choices:

Depending on the application, proven solutions could include header systems for multiple tracks and car spots, choices of vacuum, pressure, or combination systems and portable and self-powered units.

Other Options Include:

- Booster for Multiple Trailers

- Choices of Vacuum, Pressure, or Combination Systems

- Portable and Self-Powered Units

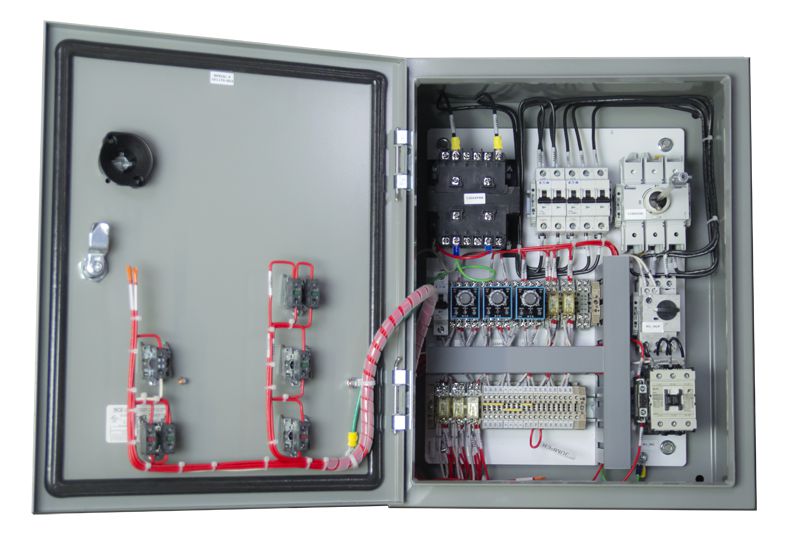

Automation

Our systems feature industrial-duty NEMA-rated control panels that automate much of the process, allowing your system to run smoothly, with less downtime.

We build control panels to meet your application needs and may include:

- NEMA-Rated Panels

- Disconnect Switch

- Primary Circuit Protection

- Industrial-Duty Buttons, Selector Switches, and Door Devices

- PLC – Programmable Logic Controller

- Motor Starters

- HMI – Human Machine Interface

- LED Indicator Lights

- Variable-Speed Controls

- Touchscreen

- Remote Networking Capability

- Data Collection

Accessories:

Accessories that enable the operators to work safely and efficiently include easy to connect aluminum vacuum gate adapters with leak proof connections, manifolds, and flex hoses of stainless steel and food-grade rubber to mate railcars to systems.

System Support:

To adjust our scope of supply to meet your needs, US Systems can also supply peripheral components:

- Storage Silos

- Dust Collectors

- Convey Piping

- Couplers

- Elbows

- Industrial Automation Controls

- Manifolds

- Gate Adapters

- and more.