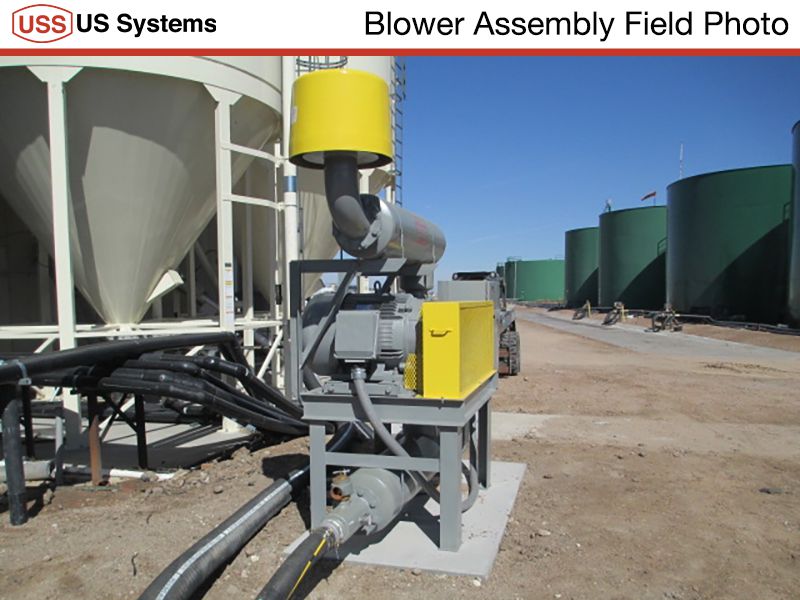

Blower Package

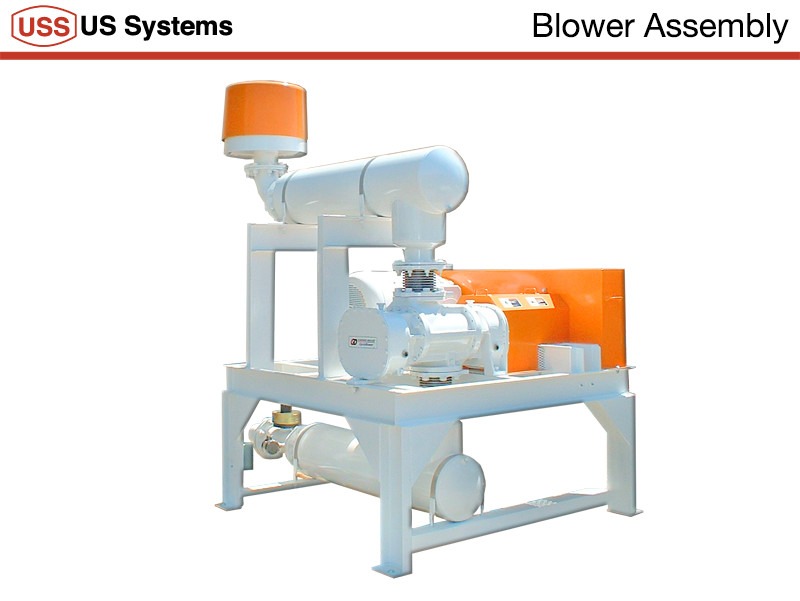

Powerful – Efficient – Built to Last

Our heavy-duty industrial blower packages are designed to KEEP YOU MOVING.

We know that our clients are going to rely on our blower packages to keep their operations running for the long haul. We size them right and manufacture them to last. USS blower packages built decades ago are still out there running processes today, keeping our customers moving.

US Systems motor-blower packages are designed, manufactured, and assembled in our shop from premium materials and components that will exceed operating conditions for continuous service. We provide skid-mounted packages for applications where portability is desired.

Sized Right and Quieter

Our blower packages don’t have model numbers. Why? Because we don’t shoe-horn whatever we happen to have in stock into your process. Our equipment is designed for optimum efficiency for the exact application, to work well and save you money in the long run. Quite simply, our motor blower packages are better than the competition and cost no more than poorly designed and built off-the-shelf units. Through our special sizing process, we will design to the specific use of the package. Sizing your package right means we can often avoid the use of a sound enclosure, where needed.

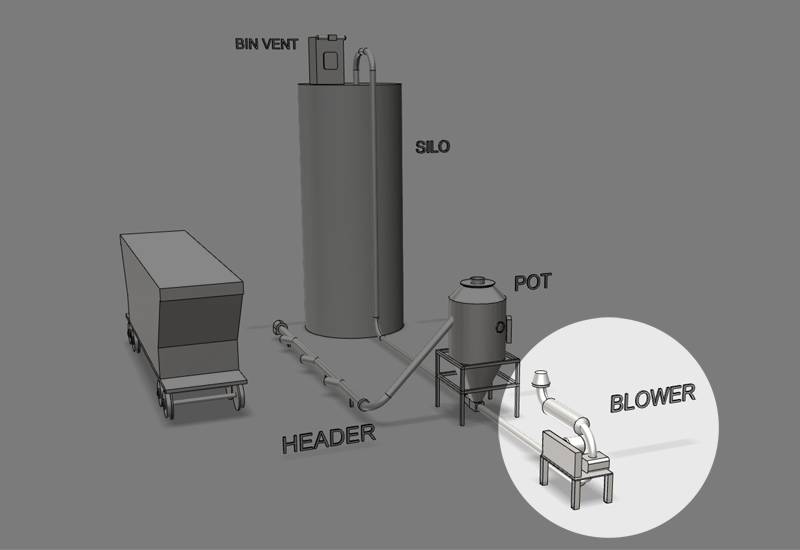

A motor blower package is the ‘air mover’ in a pneumatic conveying system. In a pressure system, atmospheric air is filtered before entering the system, then that air is powerfully blown through pipes. Dry bulk material enter the airstream from a vessel to be carried to its destination, such as a silo, or surge bin. In negative pressure systems, the air is filtered from the system side and exhausts to atmosphere.

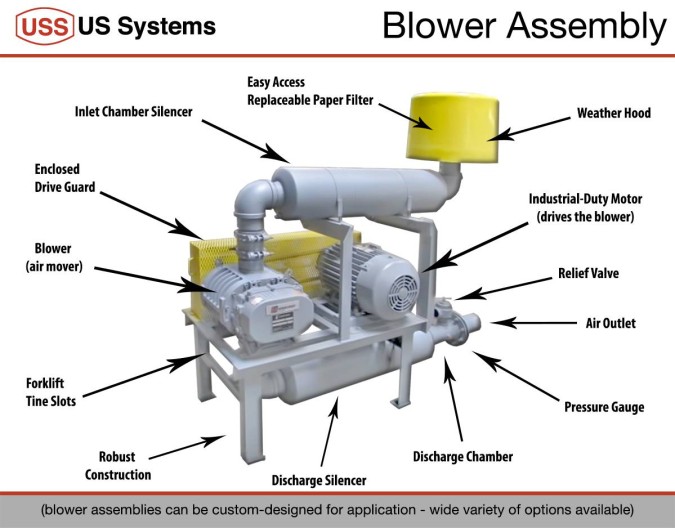

Features:

- Heavy-Duty Blower

- Heavy-Duty Motor

- Inlet Silencer (Vacuum)

- Outlet Silencer (Pressure)

- Relieve Valve

- Vacuum or Pressure Gauge

- Enclosed Drive Guard

- Robust Frame Construction

- Easy Access Filter

- Optional Aftercooler Available

- Optional Sound Enclosure Available

- Custom-Designed for Specific Application

- Portable Options Available

Benefits:

- Long-lasting

- Industrial-Duty service

- Easy-to-Read Gauges

- Easy to Maintain

- Easy to Use

- Quiet with Enclosure

- Wide Range of Applications

- Can Be Made Portable for Extra Applications

- Custom Design Means Less Wasted Energy Decreasing Total Cost of Ownership

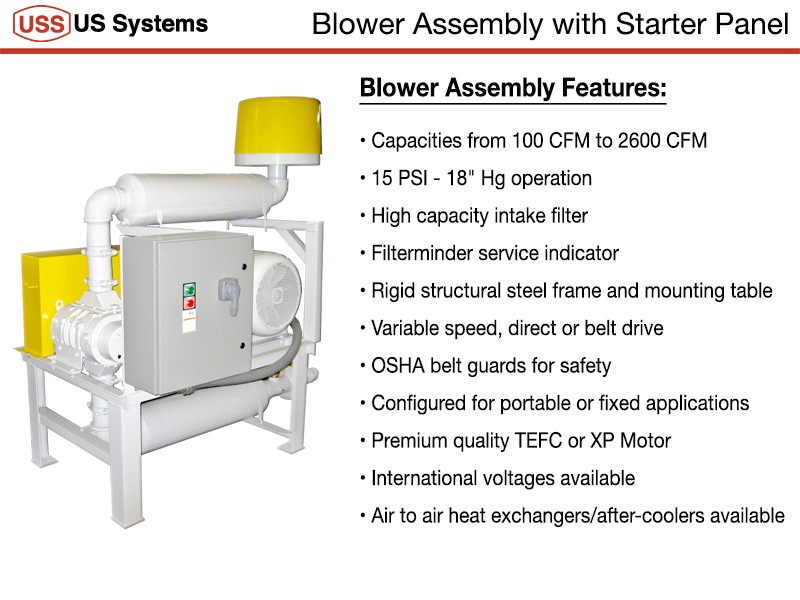

Specifications:

- Capacities from 100 CFM to 2600 CFM

- 15 PSI – 18″ Hg operation

- High capacity intake filter

- Filterminder service indicator

- Rigid structural steel frame and mounting table

- Variable speed, jackshaft, direct or belt drive

- OSHA belt guards for safety

- Configured for portable or fixed applications

- Premium quality TEFC or XP motor

- International voltages available

- Air-to-air or air-to-water heat exchangers/after-coolers available

Automation

Our systems feature industrial-duty control panels that automate much of the process, allowing your system to run smoothly, with less downtime.

We build control panels to meet your application needs and may include:

- NEMA-Rated Panels

- Disconnect Switch

- Primary Circuit Protection

- Industrial-Duty Buttons, Selector Switches, and Door Devices

- PLC – Programmable Logic Controller

- Motor Starters

- HMI – Human Machine Interface

- LED Indicator Lights

- Variable-Speed Controls

- Touchscreen

- Remote Networking Capability

- Data Collection

Additional Information:

Blowers maybe both grease and/or oil lubricated. The V-belt drive system will be totally enclosed for personnel protection and ventilated. All piping at the blower assembly is supported to relieve strains on the casing. All of our blower packages include the following:

- Pressure/Vaccuum Relief Valve

- Check Valve (Pressure Blowers)

- Low-Resistance, Easy Access Replaceable Air Filter

- Protective Filter (Negative Pressure Systems)

- High Quality Silencers

- Pressure Gauge

For Product Inquiries:

Please describe the problem you’re looking to solve – a knowledgeable and experienced engineer is ready to help.