Aftercooler

An important but little-known fact about pneumatic conveying is that the temperature of air rises 15 degrees for every PSI the air is compressed. Any good designer will understand where the heat is in the system and mitigate it if needed.

If the material conveyed is reactive to the heat we may need to mitigate the heat before the material is exposed to it.

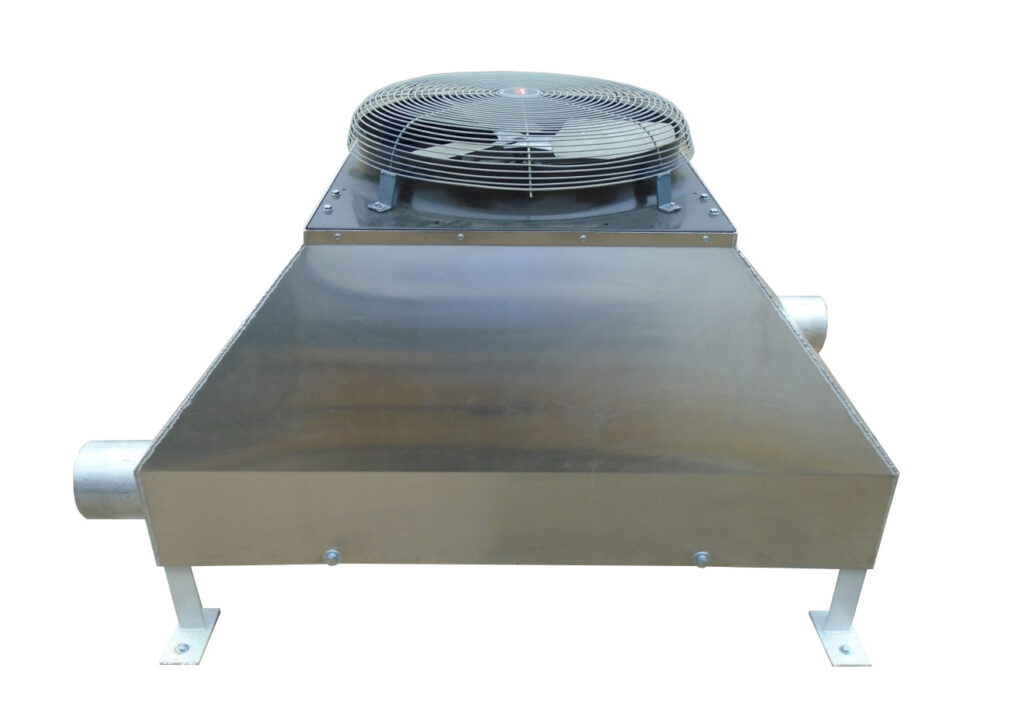

One way to mitigate the heat is with an aftercooler.

How does it work?

A standard aftercooler unit is composed of tubing (containing water or air) and fins that help it achieve cooling. When in operation, ambient air is pulled into the aftercooler to help remove moisture from the compressed air by condensation while reducing process temperatures to satisfactory levels. Compressed air aftercoolers are manufactured as either water or air-cooled variants.

For air-cooled compressed air aftercoolers, ambient air is directed over tubes containing hot compressed air to remove generated heat in a heat exchange process. In a water-cooled version (also called an air-to-water cooler), water is channeled through tubes running alongside compressed air pipes to achieve cooling.

To order: please specify the inlet and outlet type and sizes and the required airflow.