Ceramic-Backed Elbows & More

When it comes to fighting abrasion, US Systems “has your back.”

Maintenance costs, loss of material, and downtime can result from abrasive material wearing a hole in your elbow.

Mitigate these unnecessary costs with a ceramic-backed elbow that will last longer.

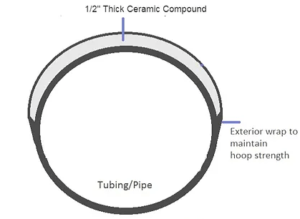

Our ceramic-backed elbow has a jacket across the back of the core elbow made of approx. 1/2″ of ceramic compound.

The ceramic compound has a Mohs Hardness of 9+, close to that of a diamond, which has a Mohs Hardness of 10.

Once the core elbow has worn through, the abrasion is transferred to the ceramic outer jacket and the core elbow continues to act as a static conductor.

Ends Available for All Fittings

- Plain End – Used with compression couplings

- Flanged – Plate Type 150# Pattern

- Grooved – for Victaulic-type couplings

- Quick Couplings

- Threaded – MPT or FPT

- Special Ends or Grooves – Custom Ends Available

WE CAN COAT MANY COMPONENTS THAT ENCOUNTER ABRASIVE WEAR

Give USS a call at 913-281-1010 – we’ll help find a solution that fits your application.

LIST OF COMPONENTS WE CAN TREAT WITH CERAMIC:

- Adapters/Tube and Pipe

- Bifurcated Bends

- Blow Thru Adapters

- Chutes

- Compound Bends

- Cyclones

- Dual Straight Thru Laterals

- Diverter Valves

- Double Ty’s

- Discharge Transitions

- Eductors

- Expanded Ends/Bends

- Flanged Fittings

- Flatback Ends

- Hopper Cones

- Inlet Wye’s

- Long Radius Elbows

- Long Radius Ty’s

- Manifolds

- Mitered Bends

- Offsets

- Outlet Adapters

- Parallel Wyes

- Pipe

- Pressure Fittings

- PVC Bends/Fittings

- Receivers

- Reducing Couplings

- Sampling Gates

- Segmented Elbows

- Short Radius Elbows

- Target Boxes

- Tee’s

- Threaded Adapters

- Transition Pieces

- Tubing

- Ty’s

- Vacuum Fittings

- Wear Plates

- Wye’s – YL’s

To order:

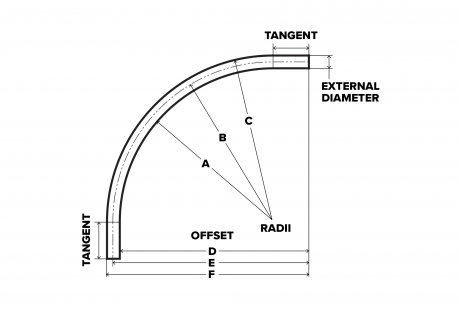

For elbows, please specify the elbow outer diameter, wall thickness, centerline radius, tangents, type of end, and construction material – carbon or stainless steel.

For all other types of ceramic-coated components please call 913-281-1010 and speak with a customer service representative.

Dimensional Diagram for Elbow Specification

STANDARD SHORT AND LONG RADIUS ELBOWS

| Tube Size | Pipe Size | Outside Diameter | Common Centerline Radii (CLR) Inches | Standard Tangent |

| 1" | 1" | 3 • 4 • 6 • 12 | 4" | |

| 1" | 1.315" | 3 • 5 | 4" | |

| 1-1/4" | 1.25" | 3 • 7.25 | 4" | |

| 1-1/4" | 1.66" | 3.5 • 4 • 6.25 | 4" | |

| 1-1/2" | 1.5" | 2.5 • 6 • 7.5 • 9 • 12 • 15 • 18 • 24 • 30 • 36 | 4" | |

| 1-3/4" | 1.75" | 2.5 • 8 • 9 • 12 • 15 • 17 • 24 • 30 • 36 • 48 | 4" | |

| 1-1/2" | 1.9" | 5 • 6 • 7.5 • 9 • 10 • 12 • 15 • 18 • 24 • 30 • 36 • 48 | 4" | |

| 2" | 2" | 5 • 6 • 8 • 8.5 • 9 • 10 • 12 • 15 • 18 • 24 • 30 • 36 • 48 | 4" | |

| 2-1/8" | 2.125" | 5 • 12 • 24 • 30 • 36 | 4-1/4" | |

| 2-1/4" | 2.25" | 3 • 9 • 12 • 15 • 17 • 24 • 30 • 36 • 48 | 4-1/2" | |

| 2" | 2.375" | 6 • 7.5 • 9 • 10 • 12 • 15 • 17 • 24 • 30 • 36 • 48 | 4" | |

| 2-1/2" | 2.5" | 4 • 6 • 9 • 12 • 15 • 17 • 24 • 30 • 36 • 48 | 5" | |

| 2-3/4" | 2.75" | 9 • 21 • 17 • 30 • 36 • 48 | 5-1/2" | |

| 2-1/2" | 2.875" | 9 • 12 • 12.5 • 15 • 17 • 24 • 30 • 36 • 48 • 60 | 5" | |

| 3" | 3" | 7.5 • 9 • 10 • 12 • 15 • 18 • 24 • 30 • 36 • 48 • 60 | 6" | |

| 3-1/4" | 3.25" | 15 • 17 • 30 | 6-1/2" | |

| 3-1/2" | 3" | 3.5" | 6 • 8.75 • 9 • 12 • 15 • 16 • 18 • 20 • 24 • 30 • 36 • 48 | 7" tube • 6" pipe |

| 3-3/4" | 3.75" | 17 • 24 • 32 • 36 • 48 | 7-1/2" | |

| 4" | 3-1/2" | 4" | 6 • 10 • 12 • 16 • 18 • 20 • 24 • 30 • 32 • 36 • 48 • 60 | 8" tube • 7" pipe |

| 4-1/4" | 4.25" | 16 • 30 • 36 • 48 • 60 | 8-1/2" | |

| 4-1/2" | 4" | 4.5" | 9 • 12 • 16 • 18 • 20 • 24 • 30 • 32 • 36 • 48 • 60 | 9" tube • 8" pipe |

| 4-3/4" | 4.75" | 36 • 48 • 60 • 72 | 9-1/2" | |

| 5" | 5" | 12.5 • 17 • 22 • 24 • 30 • 36 • 42 • 48 • 60 • 72 | 10 | |

| 5" | 5.563" | 15 • 20 • 24 • 30 • 36 • 42 • 48 • 60 • 72 | 10 | |

| 5-1/2" | 5.5" | 30 • 36 • 42 • 48 • 60 • 72 | 11 | |

| 6" | 6" | 15 • 18 • 24 • 30 • 36 • 42 • 48 • 60 • 72 | 12 | |

| 6" | 6.625" | 18 • 24 • 30 • 36 • 42 • 48 • 60 • 72 | 12 | |

| 8" | 8" | 48 • 60 • 72 | 16 | |

| 8" | 8.625" | 24 • 32 • 40 • 48 • 60 • 72 | 16 | |

| 10" | 10.75" | 40 • 50 | 20 |