Pneumatic Railcar Unloading System

Choose the Pneumatic Solution for Railcar Unloading

Faster Rates – Less Downtime – Superior Dust Control

Pneumatic conveying is an elegant, efficient solution that allows us to engineer systems without excessive use of horsepower.

Our unique design concept provides for limited maintenance and prevents premature wear on components. Savings in the use of horsepower translates into less system heat and product degradation.

There are many advantages to pneumatic railcar unloading compared to mechanical conveying. Less moving parts means less breakdowns, and an enclosed system means easy dust control. Another important advantage is flexibility in routing – we can convey material to places others can’t.

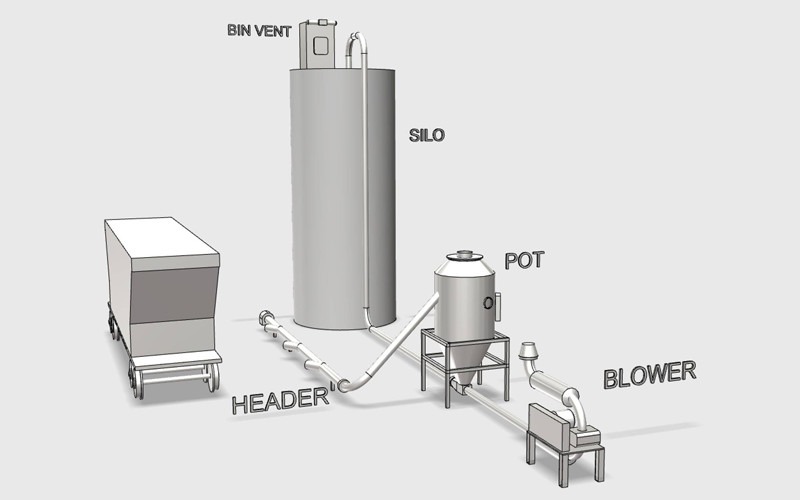

Essentially, a cycling pneumatic conveying system sucks dry bulk material through a pipe from one location (railcar, truck trailer, silo, etc.) into a temporary vessel called a ‘pot’, and then blows the material in a pipe to a destination (railcar, trailer, silo, bulk bagger, process etc.).

Pneumatic conveying companies that manufacture Rotary Valves are incentivized to use them wherever possible. They have their place and we will recommend them as necessary. However, we can often engineer a solution avoiding their use altogether with our cycling conveyors.

Our Cycling Conveyor without Rotary Valve Eliminates:

- Blow-by Air

- Worn Shaft Seals

- Bent/Worn Rotors

- Wasted Horsepower and Energy

- Worn Out Housings

- Chain Drive Maintenance

- Valves with Inherent Leaks

High Rates

These high-rate pneumatic railcar unloading systems employ either diesel or electric driven portable units that can range from 10 to 200 horsepower and can move material at a rate of one to one-hundred ton per hour.

We Achieve High Rates with All Types of Railcars:

- Hopper

- Airslide

- Pressure Differential Cars

We Provide Choices:

Depending on the application, proven pneumatic railcar unloading solutions could include header systems for multiple tracks and car spots, choices of vacuum, pressure, or combination systems and portable and self-powered units.

Other Options Include:

- Booster for Multiple Trailers

- Choices of Vacuum, Pressure, or Combination Systems

- Portable and Self-Powered Units

Automation

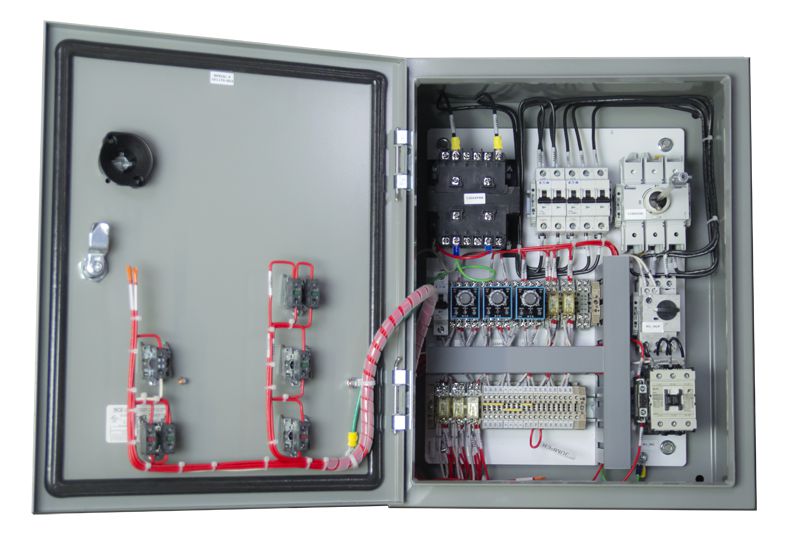

Our railcar unloading systems feature industrial-duty NEMA-rated control panels that automate much of the process, allowing your system to run smoothly, with less downtime.

We build control panels in-house to meet your application needs and may include:

- NEMA-Rated Panels

- Disconnect Switch

- Primary Circuit Protection

- Industrial-Duty Buttons, Selector Switches, and Door Devices

- PLC – Programmable Logic Controller

- Motor Starters

- HMI – Human Machine Interface

- LED Indicator Lights

- Variable-Speed Controls

- Touchscreen

- Remote Networking Capability

- Data Collection

Supporting Systems:

To match the environment of our customers operations, US Systems Pot, boosters, and supporting systems are designed to be especially rugged. Unlike our competitors, we custom-design our systems to fit your existing systems, not the other way around.

Each US Systems Pot features:

- Stainless, Aluminum, or Carbon Steel Construction

- Visual Inspection Sight Glasses

- User-Friendly Access/Clean-Out Ports

- Manual or Automatic Controls of Pneumatic and Electrical Functions

- Premium Components Designed to Last

- We Offer 12VDC, Pneumatic, or 120VAC Options for Controls

Accessories:

Accessories that enable the operators to work safely and efficiently include easy to connect aluminum vacuum gate adapters with leak proof connections, manifolds, and flex hoses of stainless steel and food-grade rubber to mate railcars to systems.

System Support:

To adjust our scope of supply to meet your needs, US Systems can also supply peripheral components:

- Storage Silos

- Dust Collectors

- Convey Piping

- Couplers

- Elbows

- Industrial Automation Controls

- Manifolds

- Gate Adapters

- and more.

No Pit? No Problem.

Pits are nice for many reasons as you can spot a car over it and open the hoppers and allow the material to dump out pretty quickly. If a pit isn’t an option then pneumatic vacuum/pressure railcar unloading is a great way to transfer material.

Pits come with their own pitfalls, which can be avoided with a pneumatic system.

Here’s why:

Pits are essentially a railroad “bridge” to carry the weight of a train including the locomotive and the heaviest railcars fully loaded. Engineering and construction of pits is a lengthy, time consuming, and expensive process. Pits are often near the ocean, lakes, or other subterranean water tables in areas not practical for dry material handling. Others have “confined space” issues as defined by OSHA or other safety authorities. Because of this, pits, no matter how clean and dry, are still considered “confined spaces” and make them very complicated to access for service, etc. Add to that the fact that they need sump pumps and need to be checked often it can become impractical or undesirable to have one.

Dry material handling machinery needs to have ready access and the confined space issue is a an obstruction to operations keeping everything clean, dry, and running properly. Spill cleanup is a fact of life for dry material handling under railcars, so pits must also be vacuumed out by sewer cleaning vac trucks on a regular basis. Pits are exposed to the elements like rain and snow. Also, the related underground mechanical equipment used to convey the material out of the pit can be difficult to perform maintenance on.

With a pneumatic conveying system, you simply place a USS railcar discharge adapter pan under the railcar. Put our pneumatic conveying system into auto and your material gets quickly and efficiently swept away in an airstream. It’s a simple, elegant, and cost-effective way of avoiding the pitfalls of a pit altogether.

Call or message USS if you don’t have a pit. We’ll engineer a solution that will keep your material moving for the long-haul.