Industrial Dust Control Systems

EPA Compliance – Eliminate Nuisance Dust – Vent Pneumatic Offloading of Material

We design and manufacture Bin Vents, Bag Houses, Vacuum Filter Receivers, Cyclones, and Wet Filters. These systems are widely used in the chemical, plastics, mineral, and food industries

Dust control is an extremely important aspect of the material handling industry, in particular the application of pneumatic conveying.

A dilute-phase pneumatic conveyor uses air suspension to move material in a conveying air stream from location to another. If a property of the material is such that it is not dusty, a positive-pressure conveying stream can be discharged directly into the receiving vessel and the air can be vented to atmosphere. In negative-pressure systems, material can be discharged into a combination filter-receiver. If, however, material is dusty, then filtration maybe necessary.

It’s an important consideration in the design of a pneumatic conveying system. There are critical performance issues at stake in the performance of negative pressure and low pressure pneumatic conveying. Let’s visit each of the solutions one by one.

Pictured above is a vacuum filter receiver used in a US Systems engineered and manufactured pneumatic conveying system consisting of a blower package, filter receiver, silo, slurry mixer, bin vent, piping, and accessories. This particular system is used to convey sodium sulfate from a railcar to a silo at a packaging plant in Louisiana.

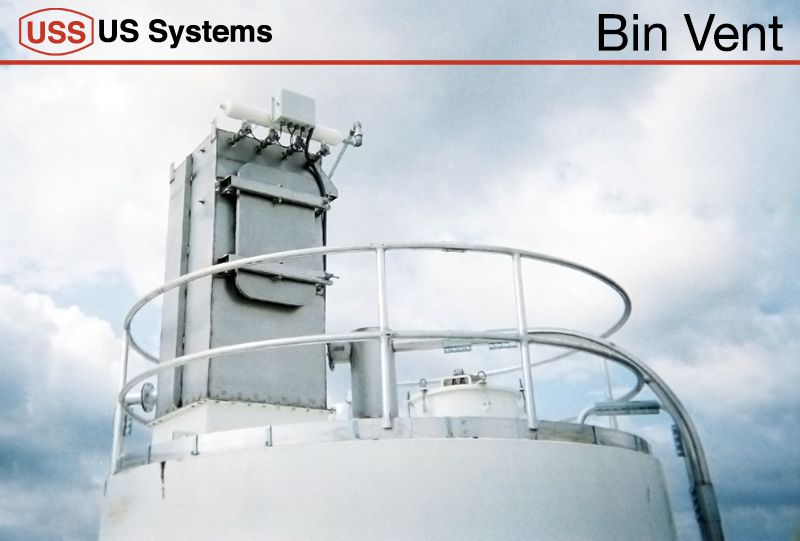

USS Bin Vent with Pulse Jet Technology

It’s important to get the air-to-cloth ratio right when selecting a dust collector. If you have more filter media than you really need, you may be spending more on your dust collector than you need to. But skimping on filter media can have serious adverse impacts on filter life, equipment life, and the overall efficiency and effectiveness of your system.

When air-to-cloth ratio is too high (e.g., not enough filter media for the airflow and volume of particulates you are producing), dust is driven deeply into the filters faster than it can be pulsed off by the filter pulsing system. As dust accumulates, negative pressure builds up on the clean side of the filter, which makes it even harder for the pulsing system to push dust out of the filter and into the containment bin. This causes rapid filter clogging, significantly reducing filter life. Facilities will find that the costs of frequent filter replacements, in terms of both consumable costs and maintenance time, will rapidly outweigh any savings gained by choosing a dust collector with less filter media. US Systems has the knowledge and experience necessary to size your filter correctly for the application.

USS Bin Vent with Pulse Jet Technology

When material discharges into a silo, the air must be allowed to escape. For dusty material that air must be filtered before venting to atmosphere. That’s where the Bin Vent with Pulse Jet Filter comes in.

In operation, air enters from the high pressure vessel through the bin vent to the low pressure atmosphere. The material passes through tubular filter media leaving the dust behind. These filter tubes are elongated to allow plenty of surface area for air to pass through in a small amount of space.

Either on a timer or by pressure switch, a jet of compressed air is periodically puffed into the center of the filter tubes, shaking and blowing the dust from the surface of the tubes. US Systems provides rugged, long-lasting filter media specified for your material. We continue supporting your system by making it easy to reorder filter media when the time comes.

USS Bag House

“Bag House is a colloquial term for a very large bin vent, sometimes containing hundreds of filters and are large enough for a person to enter to change the filters.

Bin Vent/Bag House with Pulse Jet Features:

Standard:

- Bottom, side, or top-access via top-door or walk-in plenum

- Utilizes self-Cleaning Pulse Jet technology

- Tool-less access door

- Welded safety grate

- NEMA timer controls

- Differential pressure gauge

- Stainless, painted carbon steel, or aluminum construction

- Laser-cut tube sheets

- Solid state industrial controls and automation

Specify:

- Exhaust fan to induce draft

- Portable unit needed

- Particulate monitor (monitors the clean side for particulates)

- Support lugs and optional legs

- Top-load or Bottom-load type

- Flange size

- Ladder and Safety Cage for Top-Access

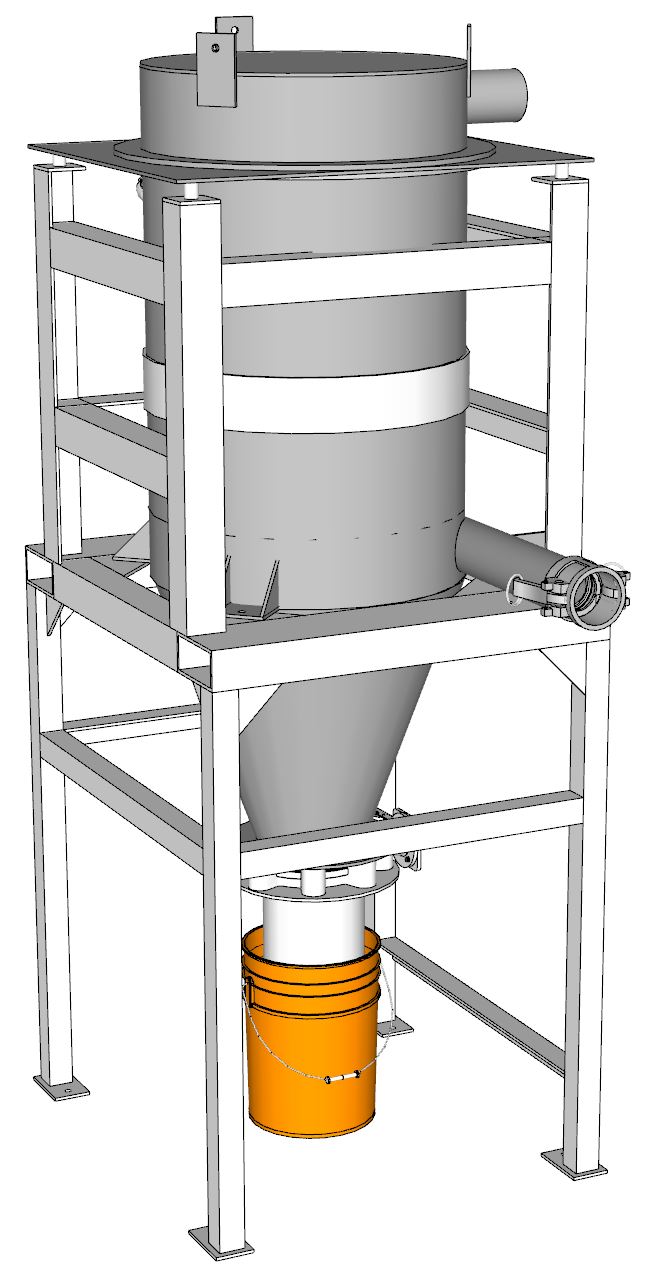

USS Vacuum Filter Receiver

Vacuum filter receivers combine the pulse jet self-cleaning ability of our bin vents with the receiver in one system. They work in either Induced Vac or Direct Vac mode.

Filter Receiver Features:

- Uses Self-Cleaning Pulse Jet Technology

- Differential pressure gauge

- Vacuum-rated vessel structure

- Inlet baffle plates standard

- Stainless, painted Carbon steel, or aluminum construction

- Laser-cut tube sheets

- Solid-state controls for automation

- Portable units available

- Davit Head available

- Particulate monitor available

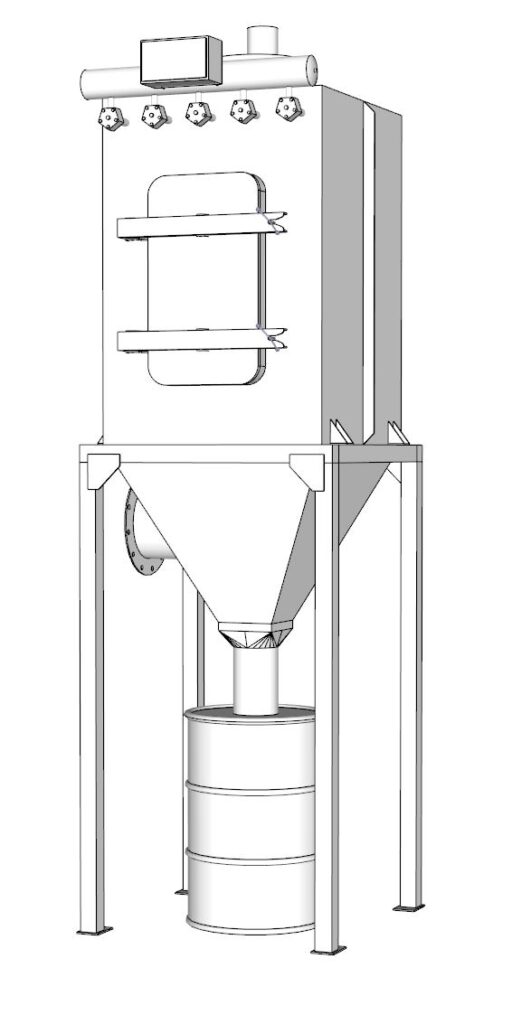

USS Pulse-Jet Dust Collector

This USS Dust Collector utilizes reverse pulse-jet technology to shoot a blast of air down the inside of the filter thereby creating a shockwave that knocks dust from the outside of the bag or cartridge.

Perfect for any kind of industrial dust control application. Usually used where compressed air is available.

USS Shaker Filter Dust Collector

This USS Shaker Filter Dust Collector utilizes hundreds of small tubular filters for a large surface area and a shaker motor to shake the dust from the filters. Perfect for where compressed air is unavailable or undesirable.

Often mounted on a trailer and used for transmodal applications where dust venting is required.

USS Cyclone Separator

We manufacture standard cyclones and engineer solutions to your most difficult problems. If you’re scratching your head about something give USS a call.

A US Systems Cyclone uses vortex separation to remove particles from air. Air and material discharges into the cyclone at a high speed from a pneumatic conveying system. The material drags downward in a spiral along the walls by gravity as the air flows upward toward the cyclone outlet.