Technology that keeps you moving

Pneumatic Conveying Guide

What is Pneumatic Conveying?

Pneumatic Conveying is a cost- and energy-efficient method of transporting dry bulk materials such as powders and granules from one place to another.

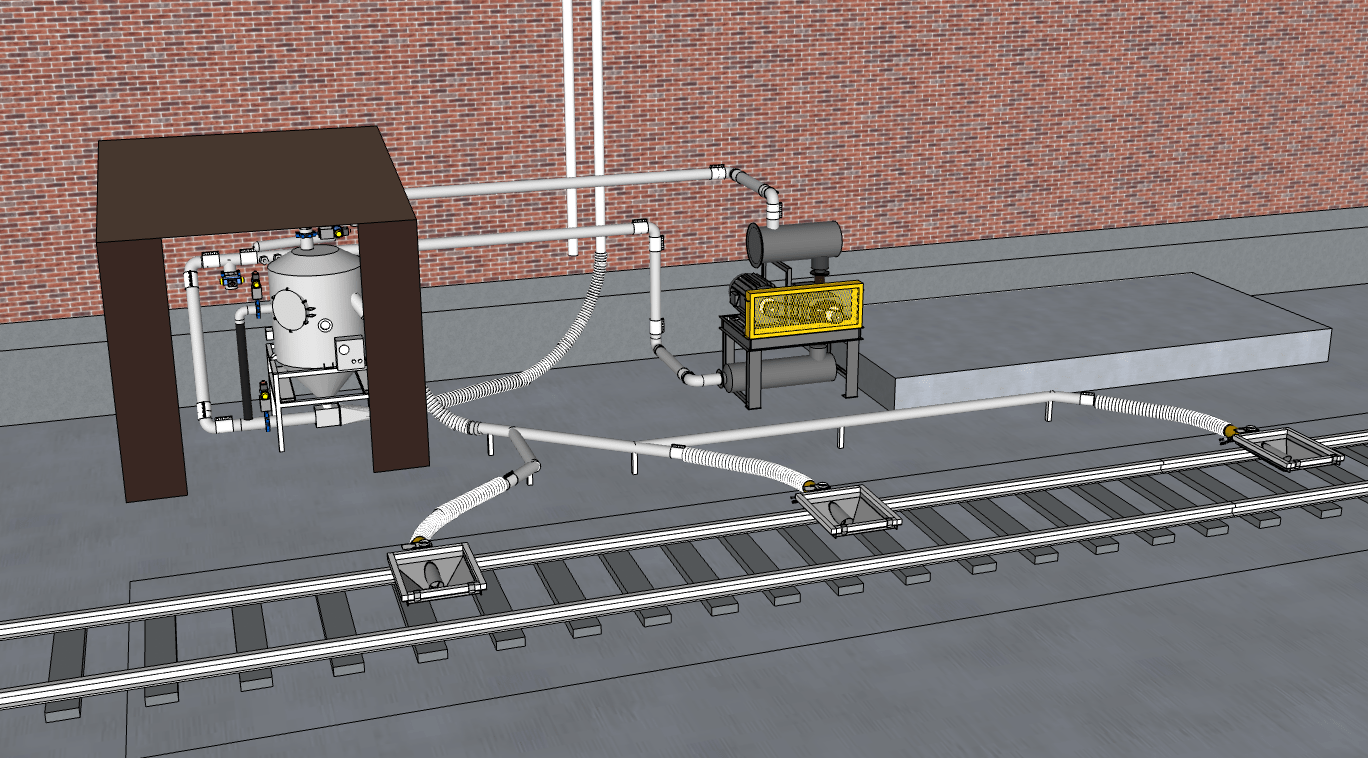

A typical example of a pneumatic conveying system that we engineer and manufacture involves conveying a material (such as polymer, lime, soda ash, plastic pellets/powder, dry milk etc.) from a railcar or truck to a silo (or vice versa) in a sealed pipe or tube.

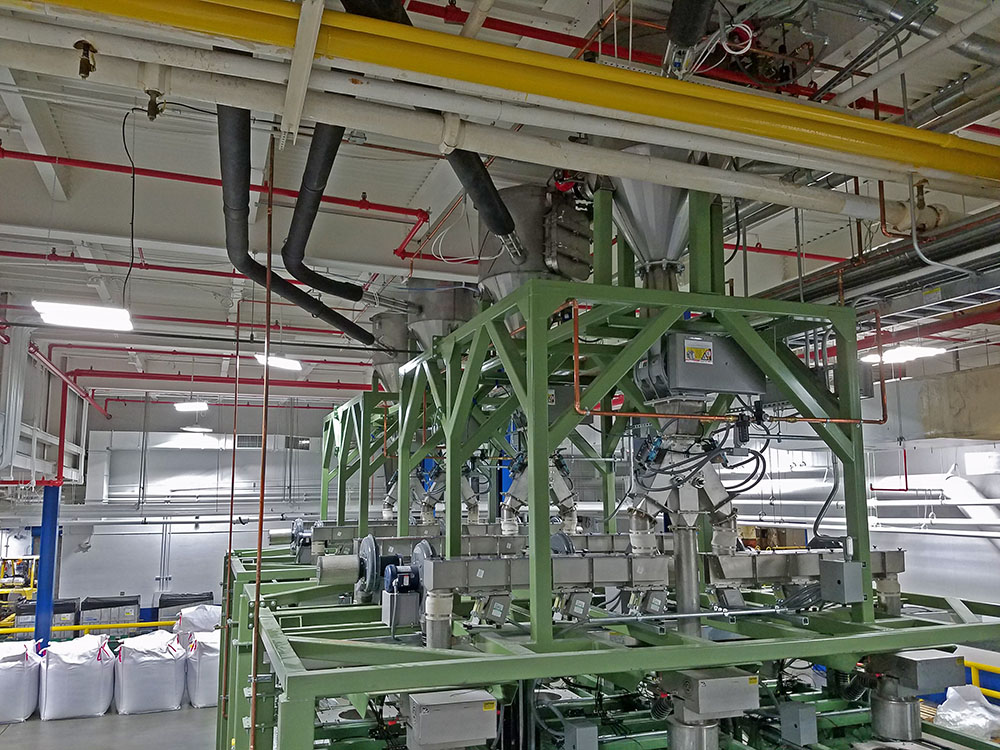

Other applications include intermodal/transloading, in-plant transfer, dust control, and portable solutions.

It’s important to understand that “pneumatic conveyor” is not a single component. It’s a collection of components working in concert as a system.

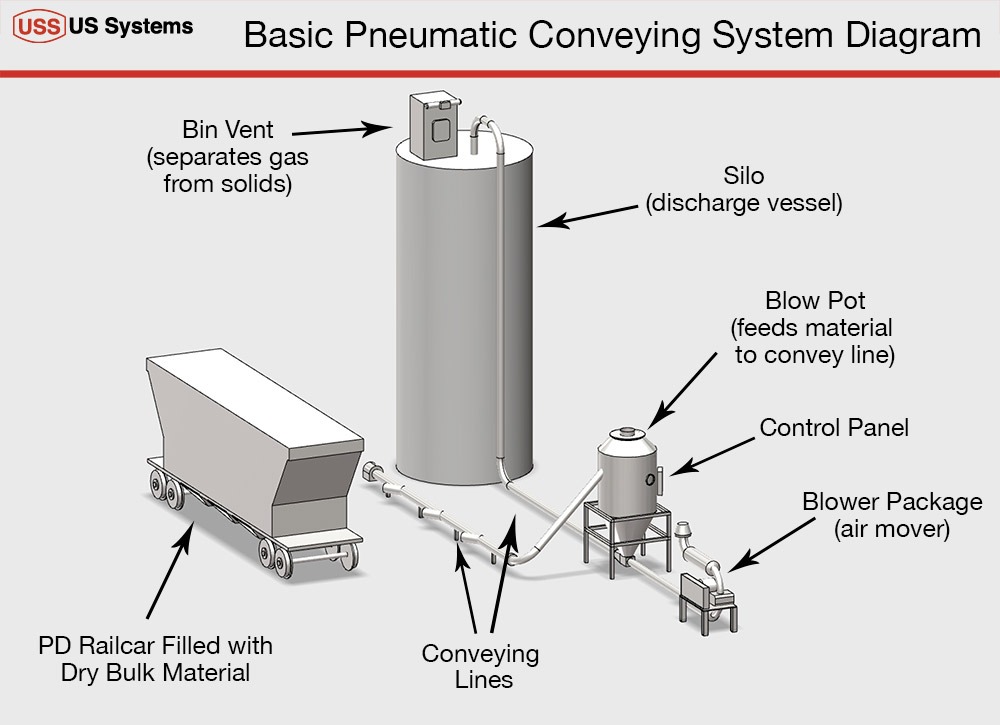

The basic components of a pneumatic conveying system:

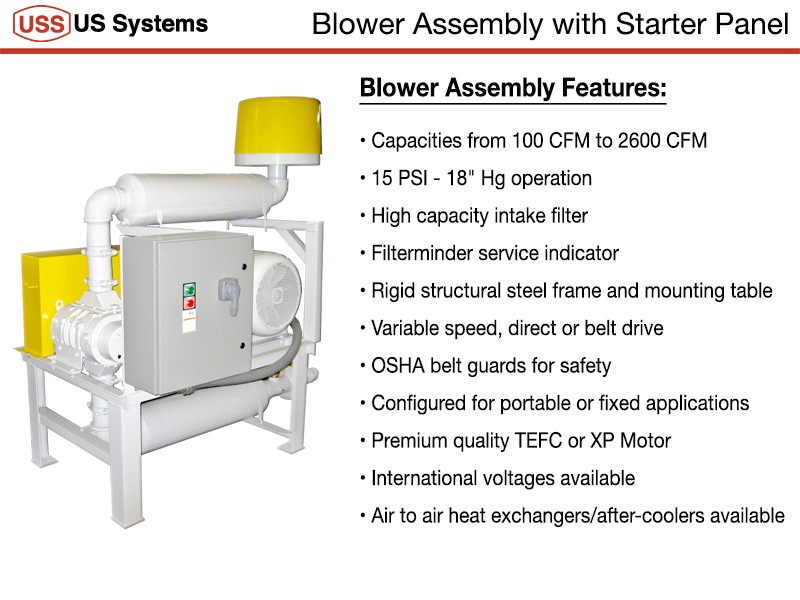

- An air mover (blower package)

- Conveying line from intake point containing material (header)

- Blow Pot (temporary vessel that feeds material into the line)

- Sealed convey line from intake point to discharge

- Discharge point (often a vessel, silo, truck, railcar, or process)

- Filtration system to separate the solids from the gas (air) at the end of the system (bin vent)

- A control panel to control and automate functions of the system

The ‘brains’ reside in the industrial control panel. This panel starts the blower, receives information from sensors, and times the operation of the equipment to achieve high rates.

The panel typically uses electricity but we’ve developed pneumatic logic controls for applications where electricity is unavailable or undesirable. Programmable Logic Controllers (PLC’s) are utilized on more complex installations. US Systems has talented automation engineers on staff and we manufacture our own controls so that we have full control over every aspect of the system.

This diagram shows the basic components of a pneumatic conveying system. In this particular system the operator connects the intake convey lines to the PD railcar and after a safety check, starts the system.

- The blower motor starts and then turns the shaft of the blower via belts or direct drive. The blower intakes filtered air, compresses it, and then pushes it through the line.

- The pot then utilizes a USS Venturi or DirectAir Valve to induce a vacuum and the material is vacuumed from the railcar into the Pot. Some systems may employ two blowers (pressure and vacuum) instead of one blower and a venturi system.

- Either by sensor automation or by manual control, the system will switch from vacuum to pressure mode and the material is blown through the sealed convey lines and into the silo where a filter will separate the gas from the material.

- This cycling process continues at high rates until the car is empty.

Advantages of Pneumatic Conveyors

- Cost savings in freight rate of bulk materials.

- Savings in the elimination of packaging costs of smaller bags and containers.

- Sealed system conveying reduces cross-contamination.

- Routing flexibility – can be transported to remote areas of plant, vertically and horizontally

- Easy dust control

- Can have several pick-up points and routes controlled with valves.

- Lower maintenance, power, and labor costs.

- Wide variety of materials can be conveyed, even ground up car batteries (re-grind)!

- Ease of automation and control

Adapted from these sources: Kraus, Milton N., Pneumatic Conveying of Bulk Materials, and Marcus, Leung, Klinzing, and Rizk, Pneumatic Conveying of Solids

The Good, The Bad, and The Ugly of Rotary “Airlock” Valves

Many times an “airlock” valve is the right component for the application – but not always. They’re expensive and have inherent issues that must be dealt with. Rotary valves are the main way we meter material and separate the pressure/vacuum zones in a system at the same time, but they don’t do either perfectly.

They’re often used as an “airlock” valve but they don’t quite lock the air between the pressure and vacuum zones of the system. This causes “blowby air” to flow across the pressure differential and the pressure loss among other resulting issues must be accounted for.

This “Blowby Air” can also cause bridging of material in the bin above, causing a no-flow scenario. These problems get worse over time as the vanes get worn down by material entrained in the Blowby Air. Air leakage through the blade tip clearances can generate high-velocity flows, which will entrain fine particles, and the resulting erosive wear can be far more serious than abrasive wear. Eventually, the pressure drop is too great and plugs occur. Airlock Valves wear out, plain and simple. Often you’ll need two so that one airlock can be in use while the other is being repaired.

Sales and repair of rotary valves are up to 30% of some large pneumatic conveying companies’ revenue. It is in their interest to sell as many of them as possible. But not every system needs one. Often, we can engineer around the need for a rotary valve altogether. Depending on the needs of the customer we’ll use a rotary valve but often we can save our customer installation and maintenance costs of system ownership by recommending a much simpler cycling loader a.k.a. “Pot” system. They’re simple, automatic, and achieve high rates without an airlock.

Seek a conveying company experienced with your particular material’s flow characteristics in order to engineer around these types of issues. For best performance, US Systems always take into account the unique circumstances of the application and the costs when utilizing rotary valves.

Our Cycling Pneumatic Conveyor Eliminates These Issues with “Airlocks”:

- Blow-by Air

- Worn Shaft Seals and packing

- Bent Rotors

- Worn and Chipped Rotors

- Wasted Horsepower and Energy

- Worn-out Housings

- Chain Drive Maintenance

- Inherent Leaks

One Size Does Not Fit All

Our motto is “Total System Responsibility” because we take the time with you to fully understand your needs and design a customized solution to solve your problem.

Pre-fab systems forced into what should be a custom application can lead to disruptions and problems once a system is installed. The problems of a one-size-fits-all solution can present themselves months later, leading to costly fixes of a problem that could have been solved by more carefully evaluating the specific circumstances of the customer’s material handling needs.

Why spend more on the system than you have to?

A custom solution doesn’t necessarily cost more, as it will often work better with less problems. Pneumatic conveying should solve a lot of headaches not create new ones.

US Systems goes the extra mile, we take the time to carefully analyze your needs, and we work harder than anyone to design a customized solution, saving time, effort, money – and headaches. All at a price that competes with the pre-fab “solution”.

Why is Pneumatic Conveying Better?

Pneumatic Conveying is a deceptively simple and clever solution to many traditional conveying problems. It’s an elegant alternative to mechanical conveyors that utilize hard-to-maintain moving parts such as belts, screws, rollers, vibrating plates, elevator buckets, drag chain, cables, discs, etc.

These systems can work well for conveying large objects, although they are limited in the ability to safely and effectively convey small and fine materials such as plastic (pellets/powders), polymer, lime, soda ash, cement, alumina, talc, silica, etc.

Pneumatic conveyors work well with foods such as flour, grain, milk, seeds, sugar, etc. In a pneumatic conveying system, these materials cannot be ground down by the conveyor or stuck between mechanical components, as they can in a mechanical system.

If you don’t want your material scattered, spilled, ground up, or undesirably dispersed outside the conveying system then suspending these particles in air through a completely enclosed pneumatic conveying system is an exquisite solution to these problems.

Commissioning and Education

Pneumatic conveying provides consistent service and uptime and saves on labor and energy costs – upwards to a quarter of the cost of a mechanical system. We can convey materials where others can’t and do so elegantly. Where our competitors might ship their system and call it quits, we provide our clients with commissioning services to ensure that you are up and running right away, the system is balanced, and your operators know exactly what they’re doing.

Support After Installation

US Systems is here to support you long after your system is installed. We offer a full complement of consumables and replacement parts. With installations running for decades, we’ve refurbished 30-year-old USS machines and placed them right back into service. It’s easy to call and order a replacement part such as a filter or fitting. Just call 913-281-1010 and we’ll make sure you get what you need, fast.

How We Control Excessive Fines and Protect Friable Material

Fines occur when pellets stick to the wall and leave material behind called angel hair, it breaks off and appears in the system. Sometimes they create a coating on the inside of the pipe and then it peels off called a snakeskin. Sometimes the pellets have small imperfections after they are cut and have an ‘ear’ sticking out. That breaks off and creates a fine. This affects the melting of the pellets and causes defects.

The causes vary with the application, and there are many ways to mitigate this phenomenon. It’s important that your pneumatic conveying company has experience working with these problems.

We have the experience and expertise to ensure common problems don’t arise when conveying your material:

- Mixtures becoming de-mixed because one ingredient absorbs moisture from the air and sticks to the wall, while the remainder of the mixture is conveyed through the line.

- A dry powdery mixture that pours readily out of a container may become a pasty mass in the conveying line due to the conveying air absorbing the heat of compression from the air blower.

- Perfumed materials may lose their odor during conveying, whereas other materials may absorb odors carried into the air inlet of the conveying system.

- An abrasive material that is successfully conveyed without erosion suddenly causes excessive erosion because the source of the material, and the method of pulverizing it has changed.

- In some cases, friable materials become degraded when air-conveyed through a pipeline that has several bends.

- Dry, finely pulverized materials will become fluidized in the conveying system and will flow uncontrollably from a bin and may even flush through screw conveyors.

- Plastics may require inert gas to prevent oxidation

Only through careful design and engineering can we preserve the properties and characteristics of the material handled.

Materials

Virtually all powder and granule materials can be conveyed. The characteristics of the material are extremely important because the system has to be tuned to the application. This is what allows for high rates and all of the benefits of pneumatic conveying.

Material Characteristics:

- Specific Gravity

- Aerated or Loose Specific Weight

- Settled Specific Weight

- Particle Size

- Abrasiveness

- Moisture Content

- Corrosiveness

- Tackiness

- Aeration and De-Aeration Characteristics

- Angle of Repose

- Toxicity

- Temperature Limitations

- Crystal Structure, Form of Particles

- Absorption of Odors

Best materials are:

- Free-flowing

- Non-abrasive

- Non-fiber

General Pneumatic Conveying System Types:

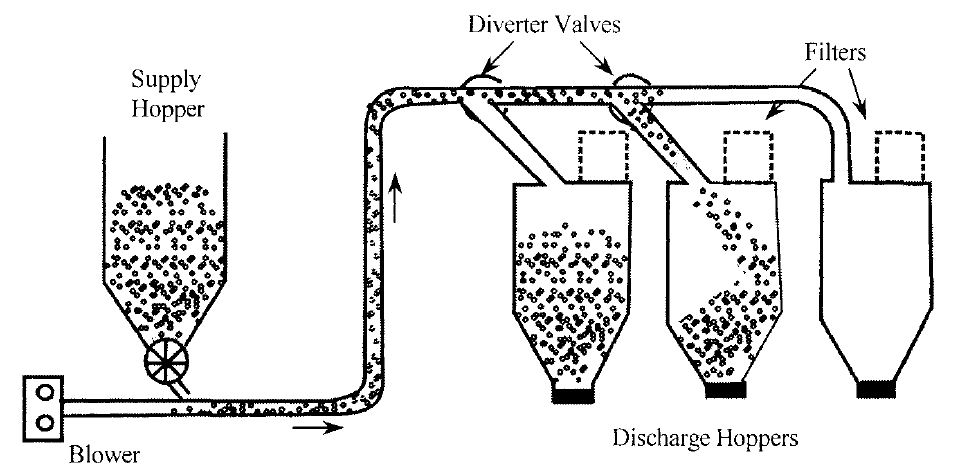

Positive Pressure

Blows material from a single source to one or multiple destinations. Generally offers higher efficiency over vacuum systems.

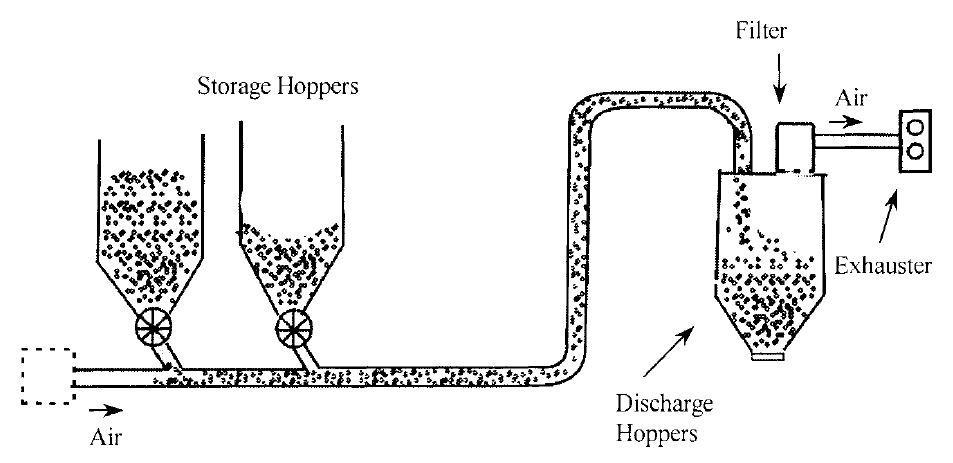

Negative Pressure

Sucks material from one or multiple sources to a destination. Doesn’t impart heat into the system. Allows for material pickup from a wand.

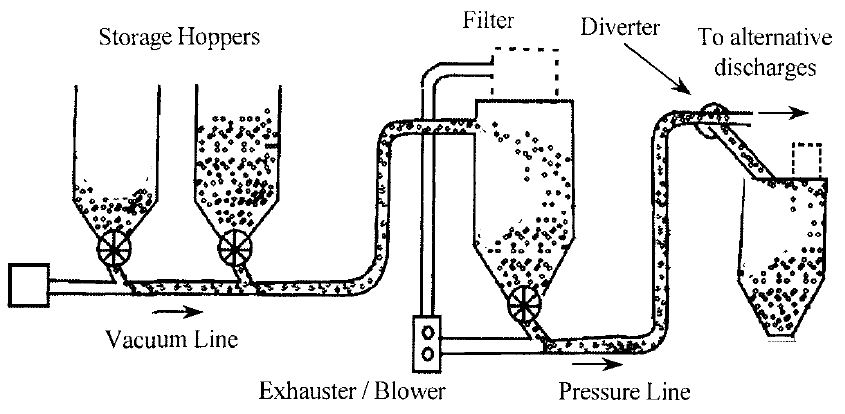

Combination Vacuum/Pressure Systems

Blows and sucks the material at the same time. Often utilizes two blowers – one each for the vacuum and pressure zones of the system. Utilizes a rotary airlock valve to separate the vacuum and pressure sides of the system.

What are “Phases” in Pneumatic Conveying Systems?

Single-Phase Flow refers to a single homogenous material flowing through the system. In pneumatic conveying this usually refers to air-only flow.

Multi-Phase Flow refers to more than one material flowing through the system. This will be the air plus any added material.

Multi-Phase Flow is then further characterized by the “solids loading ratio” which is the air-to-material ratio. These are also referred to as “flow regimes.”

Dilute Phase systems have a higher air-to-material ratio. These systems typically run air at higher velocities and lower pressures. Air is moving at a velocity high enough so that enough air particles can come into contact with the material and carry it through the system to the destination. The vast majority of pneumatic conveying applications are dilute phase.

Dense Phase systems have a lower air-to-material ratio. These systems typically run air at low velocities and higher pressures. The material must be highly uniform and aeratable as it will be aerated and flow through the system as dunes or plugs. These systems are expensive and make up a small percentage of the overall pneumatic conveying market.

There is no universally agreed-upon demarcation of when a dilute-phase system becomes dense-phase. It depends upon the bulk density and other characteristics of the material and system being employed. In general, however, a dense-phase system will require higher pressures and will use a high-pressure-rated vessel.

We Achieve High Rates with All Types of Railcars:

- Hopper

- Airslide

- Pressure Differential Cars

We Provide Choices:

Depending on the application, proven solutions could include header systems for multiple tracks and car spots, choices of vacuum, pressure, or combination systems, and portable and self-powered units.

Options:

- Booster for Multiple Trailers

- Choices of Vacuum, Pressure, or Combination Systems

- Portable and Self-Powered Units

Automation

Automation is an important aspect of any pneumatic conveying system with automatic features. Systems often need to change modes from vacuum to pressure and take in information from other vessels and processes before starting or stopping. Valves need to be opened and closed based on the mode, and pulse-jet cleaning systems need to operate based on a timed cycle.

Our systems feature industrial-duty NEMA-rated control panels that automate much of the process, allowing your system to run smoothly, with less downtime.

We build control panels to meet your application needs and may include:

- NEMA-Rated Panels

- Disconnect Switch

- Primary Circuit Protection

- Industrial-Duty Buttons, Selector Switches, and Door Devices

- PLC – Programmable Logic Controller

- Motor Starters

- HMI – Human Machine Interface

- LED Indicator Lights

- Variable-Speed Controls

- Touchscreen

- Remote Networking Capability

- Data Collection

Supporting Systems:

To match the environment of our customer’s operations, US Systems Pot, boosters, and supporting systems are designed to be especially rugged.

Each US Systems Pot features:

- Stainless, Aluminum, or Carbon Steel Construction

- Visual Inspection Sight Glasses

- User-Friendly Access/Clean-Out Ports

- Manual or Automatic Controls of Pneumatic and Electrical Functions

- Premium Components Designed to Last

- We Offer 12VDC, Pneumatic, or 120VAC Options for Controls

Accessories:

Accessories that enable the operators to work safely and efficiently include easy-to-connect aluminum vacuum gate adapters with leak-proof connections, manifolds, and flex hoses of stainless steel and food-grade rubber to mate railcars to systems.

System Support:

To adjust our scope of supply to meet your needs, US Systems can also supply peripheral components:

- Storage Silos

- Dust Collectors

- Convey Piping

- Couplers

- Elbows

- Industrial Automation Controls

- Manifolds

- Gate Adapters

- and more.

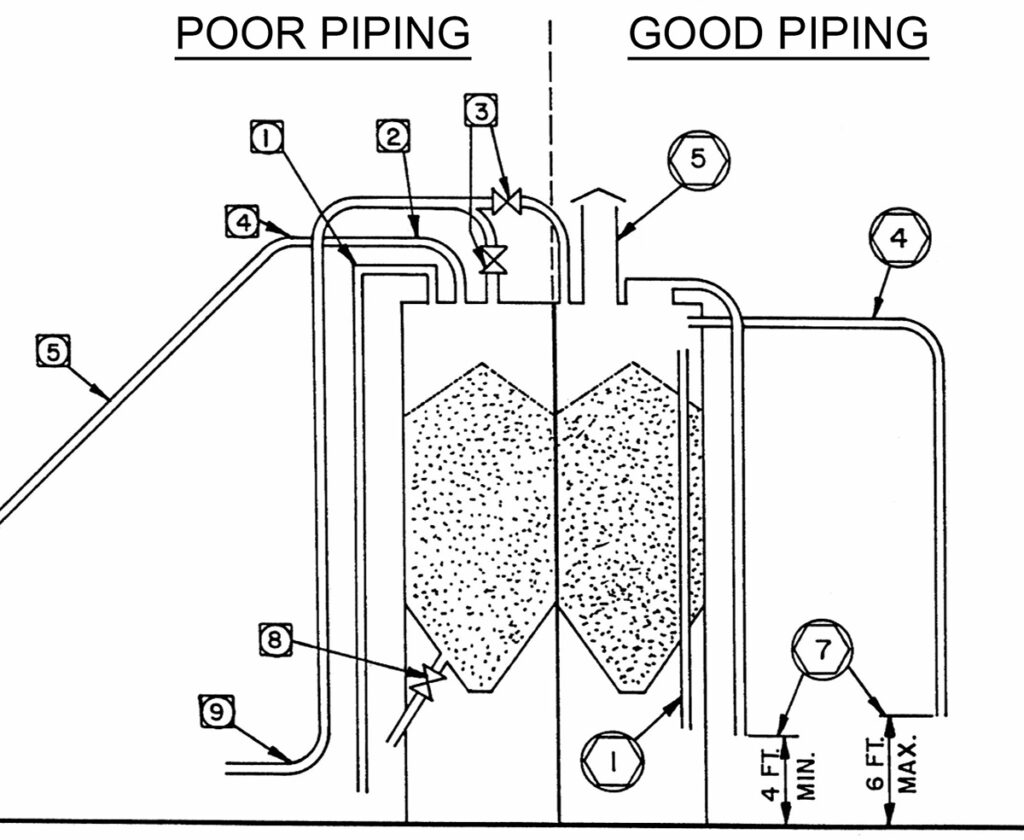

CONVEY LINE ROUTING:

Poor:

- Sharp turns or elbows.

- Useless bends or turns.

- Shut-off or diverter valves in line.

- Longer line than necessary.

- Diagonal piping. Any deviation of 5 degrees or more from strictly horizontal or vertical will increase air requirement; otherwise surging plugging will result.

- Any leak in conveying line will have similar results to no. 5.

- Inadequate venting may result in pressure build-up in receiving tank and may cause it to bulge or rupture. Note: never use other fill pipe as venting.

- Fill pipe connection at bottom of the hopper. Unloading against static pressure of product in bin reduces unloading rate substantially.

- Horizontal hook-up connection to the hose.

- Reduction in pipe size. If a trailer or portable storage unit has 4″ or 5″ piping, 4″ or 5″ piping should be provided the full distance.

Good:

- Always short as possible.

- Keep the piping strictly vertical or horizontal when possible.

- Route the piping with as few bends as possible.

- All pipe bends should have four to five-foot radius turns (sweeps or 15 X diameter of pipe).

- Adequate venting on receiving bin.

- Adequate dust collector on receiving bin when necessary.

- Ample ground clearance (4-6ft.) at hose hook-up to allow liberal natural bend of hose.

- Tight and smooth joints.

- Use a 5″ or 6″ line when a high unloading rate is required – providing adequate CFM is available.

Your partner in process success

CONCEPT – DESIGN – ENGINEERING – FABRICATION – COMMISSIONING

Proudly serving the food, grain, coffee, plastics, mineral, chemical, and pharmaceutical industries

✓ System & Component Design

✓ Engineering

✓ Manufacturing

✓ Industrial Controls

✓ Installation & Commissioning

✓ Parts Support

For Product Inquiries:

Please describe the problem you’re looking to solve – a knowledgeable and experienced engineer is ready to help.

FEATURED PRODUCT:

WHAT A USS SKIDPOT™ CAN DO FOR YOU:

FEATURES AND OPTIONS:

- All-in-One Portable Pneumatic Conveyor

- Motor and Motor Starter Panel

- Powerful blower to move material suspended in air

- V-Belt and DirectDrive options

- Forklift tine-slots for portability

- Pulse-Jet Filtration technology

- Diesel-engine driven option available

- Gauge dashboard

- Pressure/Vacuum Relief Valves for protection

- Easy tool-less access hatch

- Stainless product contact areas available

- Easy filter removal and replacement

- Available in a variety of sizes for any application

- Sturdy construction for stability and long blower life

- Easy product flow

- Flexible hoses available for inlet and discharge connections

BENEFITS:

- Custom-designed for your material

- Durable design for decades of use

- Expensive components are protected

- Product flows easily

- Safe and easy for operators to use

- Long-lasting industrial-duty components

- Can be used at one location or different site

- Capital investment moves where you need it most

- Easy removal of filtration media

- Can be paired with a USS PORTA-BAGGER™

- Easy to ship

- Easy to install

- Easy to operate

- Easy to move

- Easy to clean

- Easy to maintain

Pre-piped, pre-wired. Just add 90-100psi air and electrical.

No Air or Electricity? Compressor and Diesel options available.