Bulk Material Handling

What is Bulk Material Handling?

Bulk Material Handling is the engineering involved in designing mechanical equipment to handle and process bulk materials such as powders, pellets, aggregates, etc. It is an essential part of almost every industry; many manufacturers utilize the materials in bulk form as it simplifies a labor-intensive process which saves money and time.

Thousands of materials are bought or sold in bulk. These vary from corn to coal, food ingredients such as sugar, rubber, cement and raw materials, chemical powders, and pharmaceutical powders to plastic pellets or flakes, and more.

In a typical bulk material handling system, raw materials in bulk solids or powders are received from trucks, ships or trains. Often using a conveying system, they are unloaded to a yard or storage facility where needed in the process.

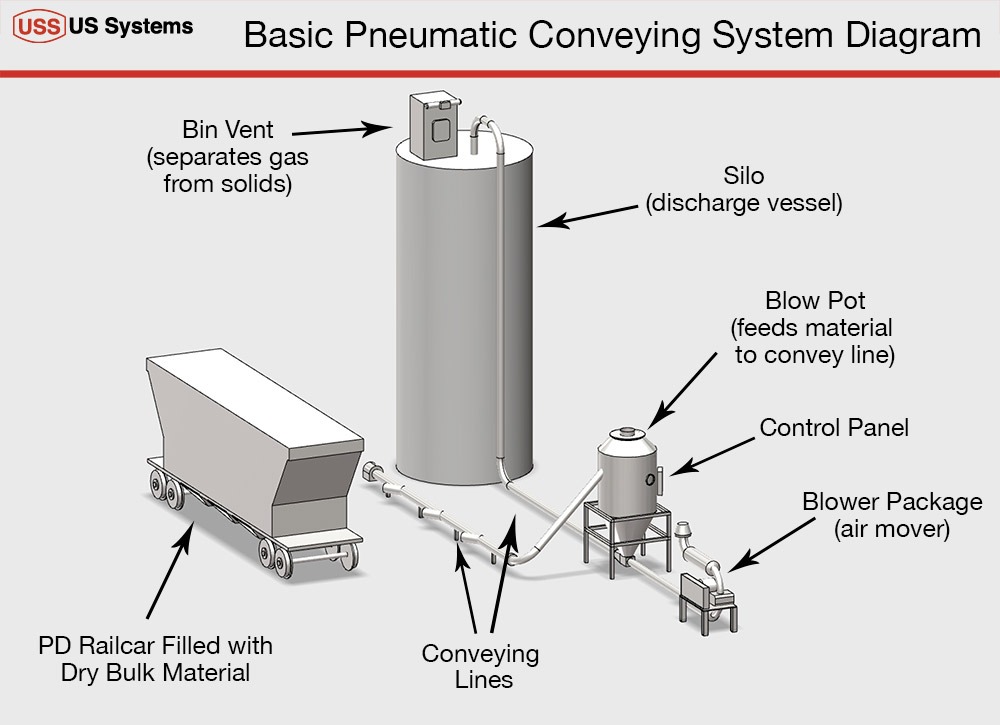

This diagram shows the basic components of a pneumatic conveying system. In this particular system the operator connects the intake convey lines to the PD railcar and after a safety check starts the system.

- The blower motor starts and then turns the shaft of the blower via belts or direct drive. The blower intakes filtered air, compresses it, and then pushes it through the line.

- The pot then utilizes a proprietary venturi system to induce a vacuum and the material is vacuumed from the railcar into the Pot. Some systems may employ two blowers (pressure and vacuum) instead of one blower and a venturi system.

- Either by sensor automation or by manual control, the system will switch from vacuum to pressure mode and the material is blown through the convey lines and into the silo.

- This process continues at high rates until the car is empty.

What is Pneumatic Conveying of Bulk Materials?

Dry Bulk Materials

Virtually all powder and granule materials can be conveyed. The characteristics of the material are extremely important because the system has to be tuned to the application. This is what allows for high rates and all of the benefits of pneumatic conveying.

Bulk Material Characteristics:

- Specific Gravity

- Aerated or Loose Specific Weight

- Settled Specific Weight

- Particle Size

- Abrasiveness

- Moisture Content

- Corrosiveness

- Tackiness

- Aeration and De-Aeration Characteristics

- Angle of Repose

- Toxicity

- Temperature Limitations

- Crystal Structure, Form of Particles

- Absorption of Odors

Advantages of Pneumatic Conveyors for Bulk Material Handling

- Cost savings in freight rate of bulk materials.

- Savings in the elimination of packaging costs of smaller bags and containers.

- Closed system conveying reduces cross-contamination.

- Routing flexibility – can be transported to remote areas of plant, vertically and horizontally

- Easy dust control

- Can have several pick-up points and routes controlled with valves.

- Lower maintenance, power, and labor costs.

- Wide variety of materials can be conveyed, even ground up car batteries (re-grind)!

- Ease of automation and control

Adapted from these sources: Kraus, Milton N., Pneumatic Conveying of Bulk Materials, and Marcus, Leung, Klinzing, and Rizk, Pneumatic Conveying of Solids

Pnuematic Systems are a Great Way to Convey Dry Bulk Material

Pneumatic Conveying of bulk materials is a deceptively simple and clever solution to many traditional conveying problems. It’s an elegant alternative to mechanical conveyors that utilize moving parts such as belts, screws, rollers, vibrating plates, elevator buckets, drag chain, cables, discs, etc.

These systems can work well for conveying large objects, although they are limited in the ability to safely and effectively convey small and fine materials such as plastic (pellets/powders), polymer, lime, soda ash, cement, alumina, talc, silica, etc.

Pneumatic conveyors work well with foods such as flour, grain, milk, seeds, sugar, etc. In a pneumatic conveying system, these materials cannot be ground down by the conveyor or stuck between mechanical components, as they can in a mechanical system.

If you don’t want your material scattered, spilled, ground up, or undesirably dispersed outside the conveying system then suspending these particles in air through a completely enclosed pneumatic conveying system is an exquisite solution to these problems.