The Pneumatic Conveyor

Easy to Use – High Rates – Low Maintenance

Understanding Pneumatic Conveying Systems for Bulk Material Handling

Pneumatic conveying offers an efficient solution for transporting dry bulk materials. At US Systems, we focus on custom-designed systems tailored to your specific application and material needs, ensuring optimal performance and value.

Custom-Designed Solutions

Each component in our systems is meticulously crafted to manage the unique properties of your materials. Moving large quantities of dry bulk through pipes requires a precise air-to-material ratio and adequate pressure. Our systems ensure that every element operates smoothly, reducing maintenance and preventing premature wear.

Design Benefits

Our innovative design minimizes maintenance and prevents premature wear of components. By optimizing the use of horsepower, our systems generate less heat and reduce product degradation, leading to cost savings and enhanced efficiency.

Pneumatic Railcar Unloading

Opting for pneumatic railcar unloading over mechanical conveying offers several advantages:

- Simpler Mechanics: Fewer moving parts mean less complexity and lower maintenance.

- Dust Control: Enclosed systems facilitate easy dust management, maintaining a cleaner working environment.

- Flexible Routing: Our systems can transport materials to locations that other methods can’t reach, offering greater flexibility.

By understanding these aspects, you can see how pneumatic conveying can enhance your material handling process. If you have any specific questions or need further information, feel free to reach out.

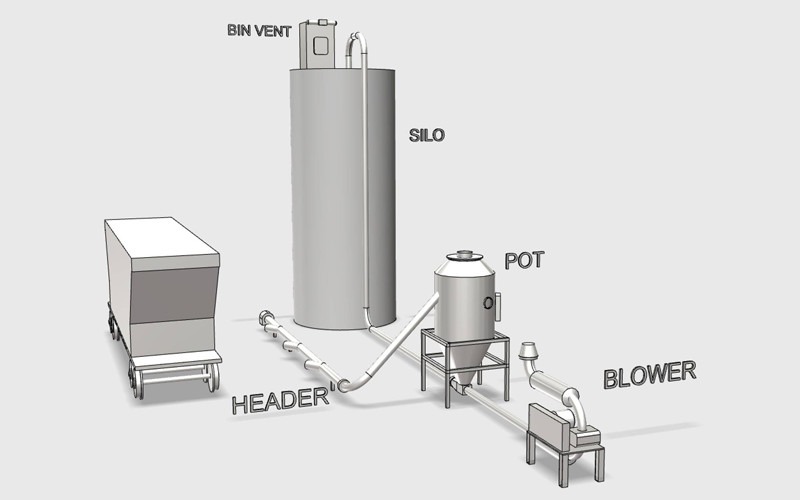

A pneumatic conveying system with a “Pot” sucks dry bulk material through a pipe or tube from one location (railcar, truck trailer, silo, etc.) into the temporary ‘Pot’, and then blows the material from the Pot in a pipe to a destination (silo, bulk bag, process etc.).

These pot-based cyclic loading systems are simple to operate, long-lasting, and low-maintenance compared with mechanical conveyors.

High Rates

These high-rate systems employ either diesel or electric-driven motors that can range from 10 to 200 horsepower and can move material at a rate of one to one-hundred tons per hour.

FEATURES AND OPTIONS:

- Powerful industrial-duty motor

- Powerful blower to move material suspended in air

- V-Belt and DirectDrive options

- Pulse-Jet Filtration technology

- Industrial-duty gauges

- Pressure/Vacuum Relief Valves for protection

- Easy tool-less access hatches & doors

- Stainless product contact areas available

- Easy filter removal and replacement

- Available in a variety of sizes for any application

- Sturdy construction for stability and long blower life

- Easy product flow

- Flexible hoses available for inlet and discharge connections

- Can be engineered with or without rotary valves

- Pickup manifolds available

- Simple check valves used to control air flow

BENEFITS:

- Custom-designed for your material

- Flexibility in destination routing

- Durable design for decades of use

- Expensive components are protected

- Safe and easy for operators to use

- Less moving parts means less headaches

- Long-lasting industrial-duty components

- Enclosed system = easy dust control

- The few wear-parts are easily swapped

- Material flows easily, avoiding “bin rash”

- Easy removal of filtration media (if utilized)

- Automated cycling of conveyor

- Easy to use

- Easy to clean

- Easy to maintain

Rotary Valves:

Selling, maintaining, fixing, and refurbishing rotary valves are up to 30% of our competitors’ revenue, so they have a vested interest in selling as many as possible. US Systems is more discerning in their use because we want to serve our customer’s needs not just our own.

Rotary valves have their place, but depending on the application and required rate, we can often avoid the use of rotary valves altogether, saving on installation and maintenance costs and eliminating these issues:

- Blow-by Air

- Worn Shaft Seals

- Bent Rotors

- Holes in Elbows

- Wasted Horsepower and Energy

- Worn Out Housings

- Chain Drive Maintenance

- Valves with Inherent Leaks

We Provide Choices:

Depending on the application, proven solutions could include header systems for multiple tracks and car spots, choices of vacuum, pressure, or combination systems and portable and self-powered units.

Other Options Include:

- Booster for Multiple Trailers

- Choices of Vacuum, Pressure, or Combination Systems

- Portable and Self-Powered Units

We Achieve High Rates with All Types of Trucks and Railcars:

- Hopper

- Airslide

- Pressure Differential Cars

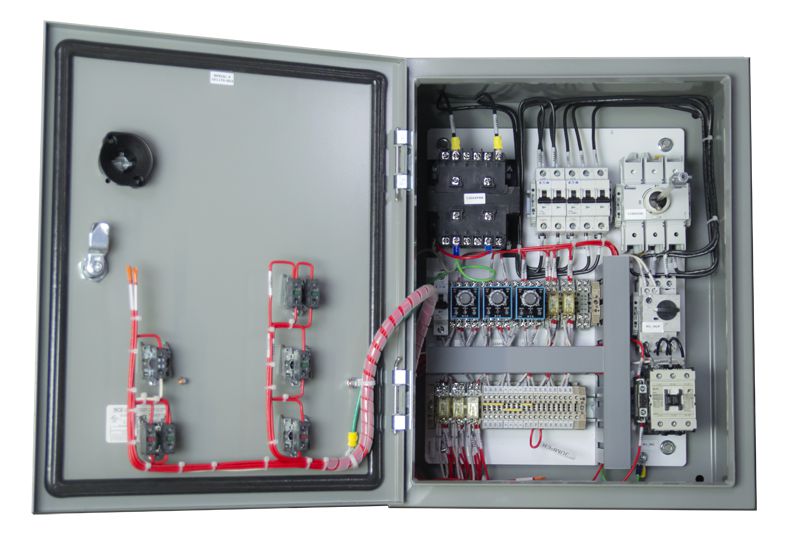

Automation

Our systems feature industrial-duty NEMA-rated control panels that significantly enhance the automation of your processes. These advanced control panels ensure that your system operates smoothly with minimal downtime, thereby improving overall efficiency and productivity.

Key Features of Our Control Panels:

- NEMA-Rated Panels:

- Designed to meet rigorous standards, these panels provide superior protection and reliability, ensuring long-lasting performance in harsh industrial environments.

- Disconnect Switch:

- Facilitates the safe disconnection of electrical power to your system, allowing for maintenance and emergency shutdowns without compromising safety.

- Primary Circuit Protection:

- Protects your system from electrical faults and overloads, minimizing the risk of damage and maintaining operational continuity.

- Industrial-Duty Buttons, Selector Switches, and Door Devices:

- Robust and durable components that offer reliable control and easy operation, designed to withstand heavy usage in demanding industrial settings.

- PLC – Programmable Logic Controller:

- Provides advanced automation capabilities, enabling precise control over various processes and functions within your system. The PLC can be programmed to execute complex tasks and ensure efficient operation.

- Motor Starters:

- Ensure the smooth starting and stopping of motors, reducing mechanical stress and prolonging the lifespan of your equipment.

- HMI – Human Machine Interface:

- Offers an intuitive and user-friendly interface for operators to monitor and control the system. The HMI displays real-time data and allows for easy adjustments to optimize performance.

- LED Indicator Lights:

- Provide visual status updates, allowing for quick identification of system conditions and enhancing operational awareness.

- Variable-Speed Controls:

- Enable precise regulation of motor speeds, optimizing energy consumption and improving process control.

- Touchscreen:

- A responsive and interactive display that simplifies system management, offering easy access to settings, controls, and diagnostic information.

- Remote Networking Capability:

- Allows for remote monitoring and control of your system, enabling timely interventions and adjustments from any location, improving responsiveness and flexibility.

- Data Collection:

- Facilitates the gathering and analysis of operational data, providing insights into system performance and helping identify areas for improvement. This feature supports predictive maintenance and process optimization.

Supporting Systems

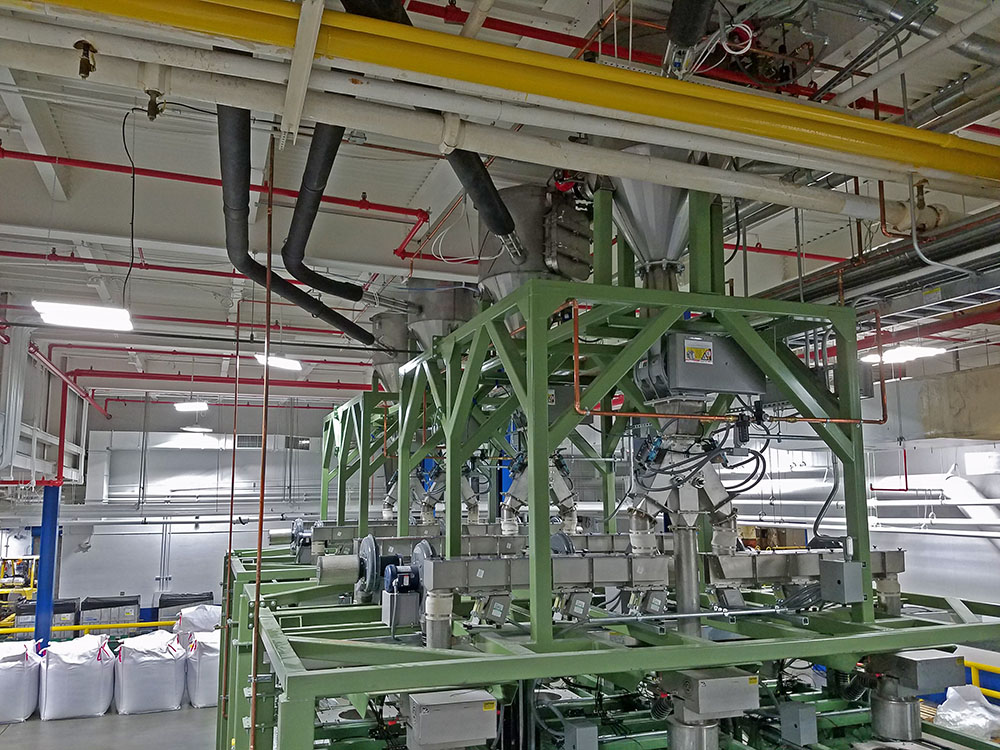

At US Systems, we understand the demanding environments in which our customers operate. Therefore, our pneumatic conveying equipment, including pots, boosters, and supporting systems, are engineered to be exceptionally rugged and reliable.

Robust Construction and Design

Each US Systems Pot is built with durable materials such as stainless steel, aluminum, or carbon steel, ensuring long-lasting performance even in the harshest conditions. This construction choice not only provides strength but also resistance to corrosion, wear, and other environmental factors.

Visual Inspection and Easy Maintenance

Our pots are equipped with visual inspection sight glasses, allowing operators to monitor the material flow and system performance without interrupting operations. User-friendly access and clean-out ports facilitate easy maintenance and cleaning, ensuring minimal downtime and maximum efficiency.

Advanced Control Options

We offer both manual and automatic control options for pneumatic and electrical functions. This flexibility allows customers to choose the control method that best suits their operational needs. Our control panels can include features such as:

- 12VDC, Pneumatic, or 120VAC Options for Controls: These options ensure compatibility with various power systems and operational requirements.

- Premium Components: All components are selected for their durability and reliability, designed to withstand rigorous industrial use.

Premium Components for Longevity

We use only the highest quality components in our systems to ensure they stand the test of time. This commitment to quality means fewer breakdowns and longer intervals between maintenance, providing customers with a dependable solution for their pneumatic conveying needs.

By incorporating these robust features, US Systems ensures that our supporting systems not only meet but exceed the demands of your operations. Whether you’re dealing with abrasive materials, high throughput requirements, or challenging environmental conditions, our equipment is designed to deliver reliable, efficient performance.

For more information or to discuss your specific needs, please feel free to contact us. Our team is ready to provide the support and solutions you need to optimize your material handling processes.

Accessories

At US Systems, we provide a comprehensive range of accessories designed to enhance the safety and efficiency of your operations. Our accessories are meticulously engineered to ensure seamless integration and optimal performance in your pneumatic conveying systems.

Key Accessories:

- Aluminum Vacuum Gate Adapters:

- These adapters offer easy connections with leak-proof seals, ensuring that your systems maintain optimal pressure and efficiency.

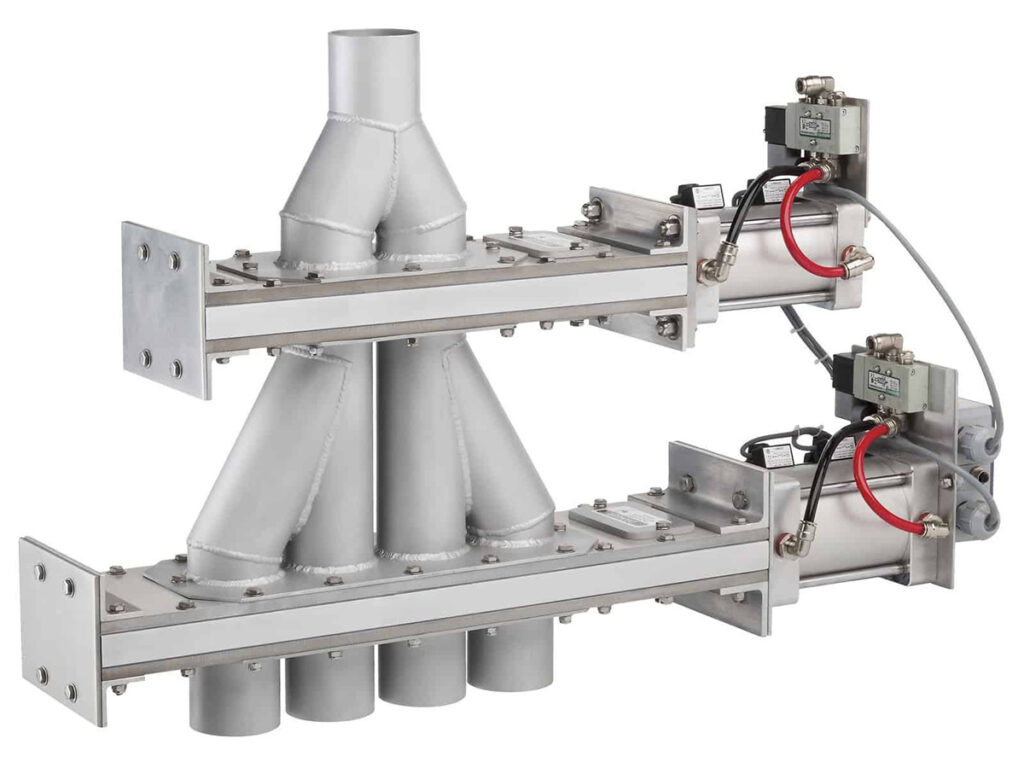

- Manifolds:

- Our manifolds are designed to distribute air evenly and efficiently, improving the performance of your pneumatic conveying system.

- Flexible Hoses:

- We offer durable, flexible hoses made of stainless steel and food-grade rubber. These hoses ensure a secure connection between railcars and your conveying system, accommodating a range of materials and applications.

System Support

To meet the diverse needs of our clients, US Systems provides a variety of peripheral components that complement our core pneumatic conveying solutions. These components are essential for creating a comprehensive material handling system that is efficient, reliable, and tailored to your specific requirements.

Peripheral Components:

- Storage Silos:

- Our storage silos are designed for the efficient storage and easy handling of bulk materials. They ensure that your materials are safely stored and readily accessible for your conveying system.

- Dust Collectors:

- Effective dust collection is crucial for maintaining a clean and safe work environment. Our dust collectors capture and contain dust, preventing it from contaminating your workspace and ensuring compliance with health and safety regulations.

- Convey Piping:

- We supply high-quality convey piping that is durable and designed to handle the specific demands of your materials. Our piping solutions ensure smooth and reliable material flow throughout your system.

- Couplers and Elbows:

- Essential for directing and connecting your convey piping, our couplers and elbows are built to withstand the stresses of pneumatic conveying. They help maintain system integrity and prevent leaks or blockages.

- Industrial Automation Controls:

- Our advanced control systems allow for precise monitoring and management of your conveying operations. These controls enhance system efficiency and provide the flexibility needed to adapt to changing operational demands.

- Manifolds:

- In addition to their role in accessories, our manifolds are crucial for distributing air in larger systems, ensuring consistent performance across all sections.

- Gate Adapters:

- Gate adapters facilitate the connection between different sections of your system, providing a secure and efficient means of directing material flow.