Pneumatic Conveying Design Factors

Designing a pneumatic conveying system requires meticulous consideration of multiple factors to ensure efficient, reliable, and cost-effective operation. Key aspects to keep in mind include bulk density, conveying distance, conveying rate, material characteristics, pick-up location, headroom requirements, construction materials, process type, upstream processes, environmental and safety considerations, and control systems.

Bulk Density

Bulk density is a primary consideration that influences the choice of air sources and vacuum receivers. Denser materials necessitate more robust equipment to handle the additional weight effectively.

Conveying Distance

The total length of the conveying line, including horizontal and vertical segments, affects energy requirements. Longer distances often demand higher air pressure or larger blowers to maintain the necessary airflow and pressure.

Conveying Rate and Batch Conveying

The desired rate of material transport, whether continuous or batch, determines airflow rates and system capacity. Continuous systems usually require higher airflow rates to maintain a steady flow of materials, while batch systems need precise control to handle specific quantities efficiently.

Material Characteristics

Understanding the characteristics of the material being conveyed is essential. Factors such as particle size, shape, moisture content, and abrasiveness impact the choice of system components and operating conditions. Abrasive materials may require wear-resistant materials for pipes and fittings, while moisture-sensitive materials might need dryers or moisture control systems.

Pick-Up Location and Material Container

Properly designed pick-up points and containers ensure seamless material transfer from storage to the conveying system, reducing material spillage and ensuring consistent feed rates into the conveying line.

Headroom Requirements

Adequate headroom is necessary for the installation, operation, and maintenance of conveying equipment. This may involve customized designs to fit within spatial constraints without compromising system performance.

Construction Materials

The choice of construction materials for the conveying system should be compatible with the material being handled to prevent issues like corrosion, wear, and contamination. Stainless steel might be used for corrosive materials, while durable polymers could be selected for abrasive substances.

Batch or Continuous Process

Deciding whether the system will operate in a batch or continuous process helps determine the appropriate equipment and control systems. Continuous processes require robust systems that can maintain consistent operation, while batch processes need precise timing and measurement controls.

Upstream Processes

Ensuring that the pneumatic conveying system integrates seamlessly with upstream processes, such as material feeders or mixers, is crucial for maintaining smooth and efficient operations. Coordination with upstream equipment can help prevent bottlenecks and ensure consistent material flow.

Environmental and Safety Considerations

Compliance with environmental regulations and safety standards is essential to prevent dust emissions, contamination, and potential hazards. Implementing dust collection systems, explosion-proof equipment, and proper ventilation enhances both environmental and occupational safety.

Control Systems and Automation

Incorporating advanced control systems and automation can significantly enhance the efficiency and reliability of the pneumatic conveying system. Automation allows for real-time monitoring and adjustments, ensuring optimal performance and reducing the risk of downtime due to manual errors.

By carefully evaluating these aspects, US Systems can develop a system that is efficient, reliable, and tailored to your specific operational needs. If you have any specific requirements or further questions, feel free to contact us.

What is Pneumatic Conveying?

Pneumatic conveying is a method of transporting bulk materials through pipelines using air or another gas as the conveying medium. This technology leverages the principles of fluid dynamics to move materials efficiently over various distances and through complex pathways, making it a versatile solution for many industries.

Key Aspects of Pneumatic Conveying:

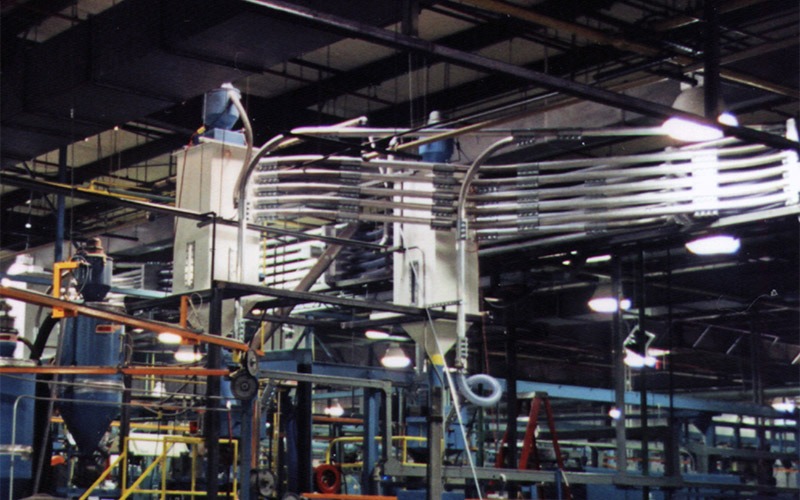

Components of a Pneumatic Conveying System

- Blowers or Compressors: Generate the airflow needed to move materials through the pipeline.

- Conveying Line: The pipeline through which materials are transported.

- Feeder: Introduces materials into the conveying line, ensuring a consistent flow.

- Receiver: Collects and separates materials from the air stream at the destination.

- Airlock Valves: Maintain the pressure differential between the conveying line and the surroundings. Used in certain circumstances with certain materials and pressures due to high maintenance costs. US Systems designs many systems eliminating the airlock altogether.

Advantages of Pneumatic Conveying

- Versatility: Can handle a wide range of materials, from powders to granules, and even small particles.

- Efficiency: Reduces manual handling and improves process automation, enhancing overall productivity.

- Flexibility: Adapts to various layout constraints and can transport materials over long distances and complex routes.

- Clean and Safe Operation: Enclosed system design minimizes dust generation and contamination, ensuring a safer working environment.

- Reduced Maintenance: Fewer moving parts compared to mechanical conveying systems, resulting in lower maintenance costs and downtime.

Applications of Pneumatic Conveying

- Food and Beverage: Transporting ingredients like flour, sugar, and grains.

- Pharmaceuticals: Conveying powders and granular materials for manufacturing processes.

- Chemical Industry: Handling raw materials and chemicals in powder or pellet form.

- Plastics: Transporting plastic pellets and resins.

- Cement and Building Materials: Moving bulk materials like cement, sand, and fly ash.

Overall, pneumatic conveying offers a reliable and efficient means of transporting bulk materials, improving operational efficiency and ensuring material integrity across a wide range of industries. Whether it’s moving delicate powders or robust granules, pneumatic conveying systems can be customized to meet the specific needs of any application.