The USS ULTRA-BAGGER™ Bulk Bag Filling Machine

Dispense Pallet -> Fill -> Weigh -> Pack -> Convey -> Repeat

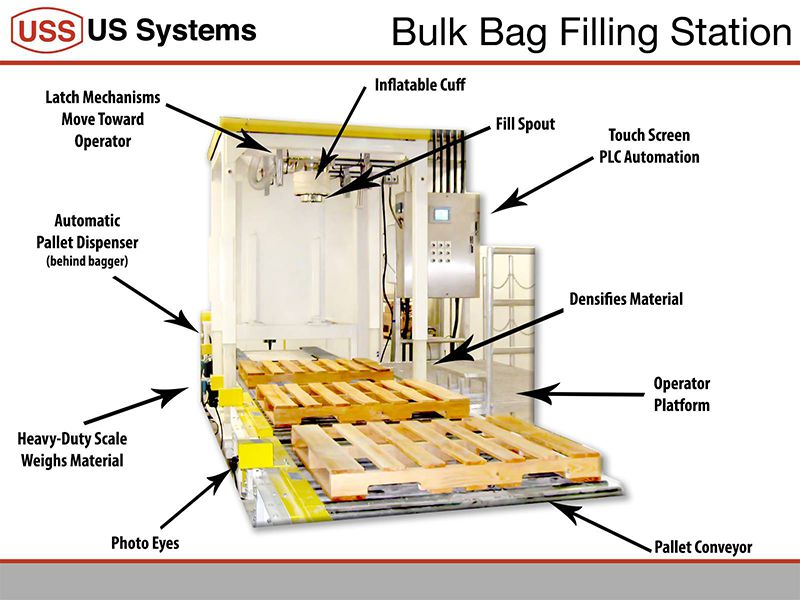

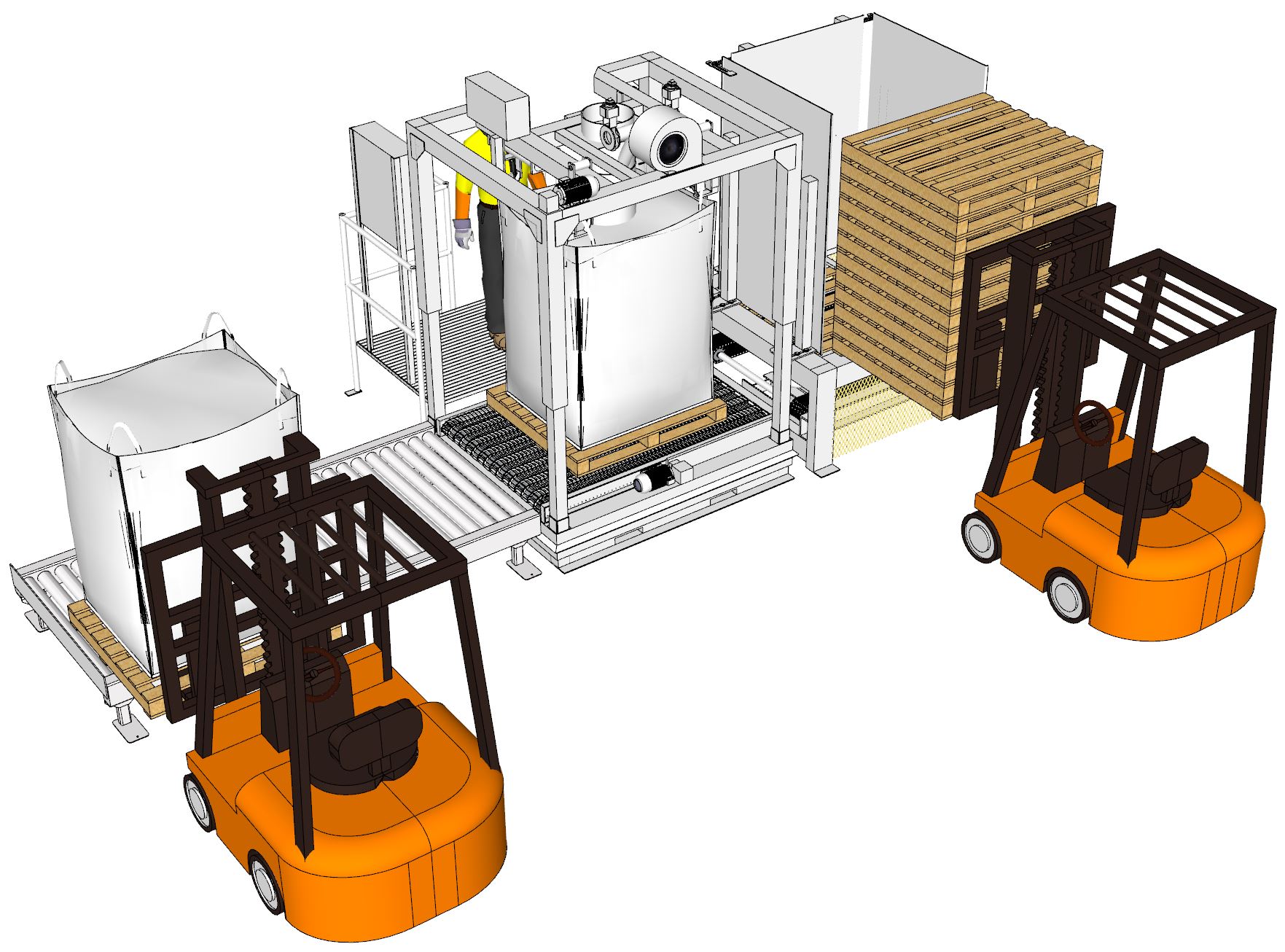

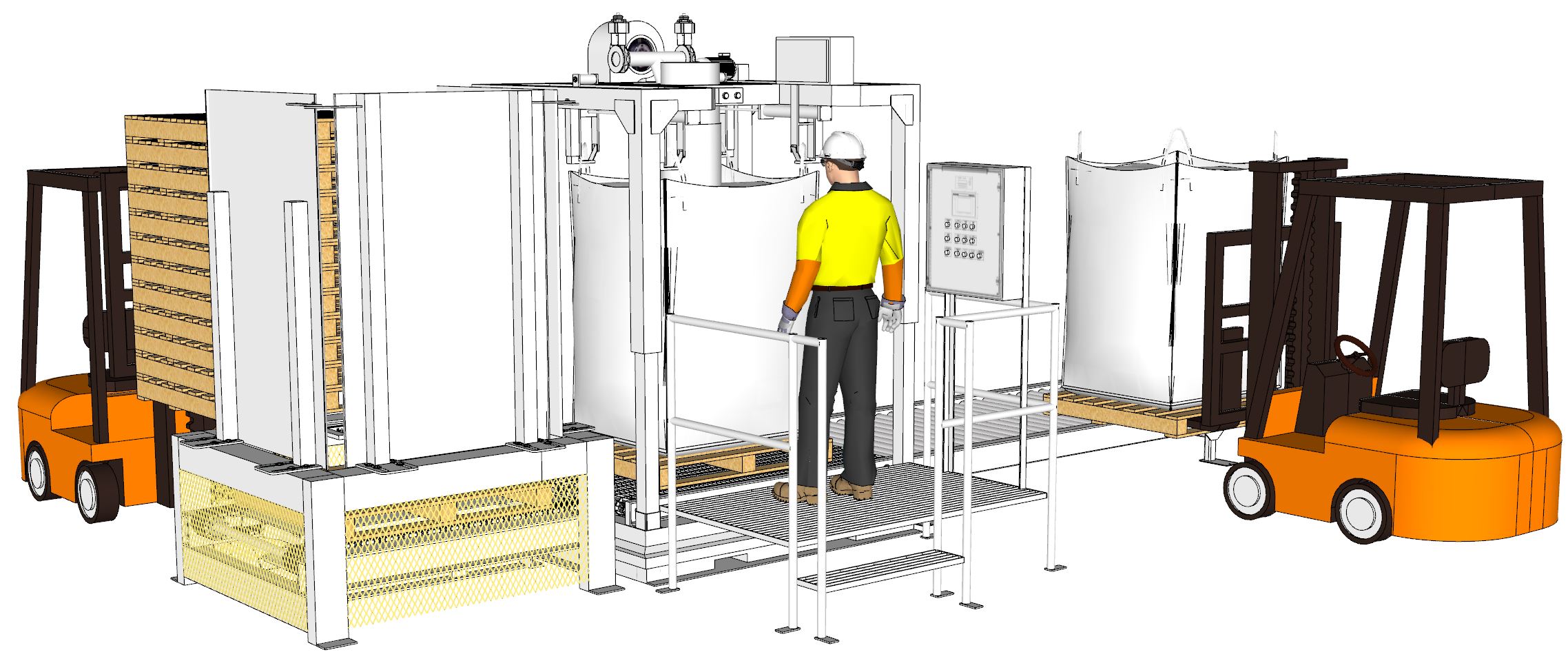

This FIBC (Super Sack) bulk bag filling machine features automatic pallet dispensing, bag hooks that retract toward the operator, automatic weighing, densification, and conveying. This station has it all – a turn-key package that saves on labor costs and measurement accuracy.

The USS ULTRA-BAGGER™ is our highest-rate bulk bag filling station. When you need to fill a lot of bags quickly, with little downtime and maintenance…this is the bagging station for you.

The elegant operation of this PLC-run station fills, accurately weighs, and packs your material in a single operation. Our patented densifier fills bags with up to 20% more product, saving space and efficiency in storage. Our densifier is so efficient that we have clients that stack bags on top of each other.

The USS ULTRA-BAGGER™ bulk bag filling station is available with or without conveyors. The unit is accessible from all four sides and can be oriented to fit your location.

Attachments for filling drums, boxes, and totes are available.

Our pallet dispenser will handle both wood and molded pallets. Pallets can be dispensed in-line or at a 90 degree angle. This option, with powered conveyor, will fully automate your operation.

The USS ULTRA-BAGGER™ Bulk Bag Filling Station fills the same way, the right way, every time. Savings are realized in manpower required, filling accuracy, reduced bulk bag cost, improved storage, and reduced shipping charges.

This video is an “oldie but goodie” look at the main features of our bagging station. Check it out!

Features and Benefits:

- Food-grade neoprene cuff inflates to seal bag

- PLC-controlled automation

- Intuitive HMI (touchscreen available)

- Motorized height adjustment for easy maintenance

- Painted carbon steel construction

- Latch mechanisms offer positive loop control

- Latch mechanisms automatically release once bag is full

- Latch mechanisms move toward operator for quick bag hanging

- Exhaust filter available or use existing dust collection system

- Optional automatic pallet dispenser available

- All features are optional, customizations welcome. Call USS to discuss your needs.

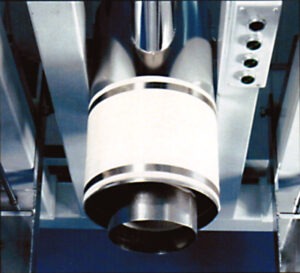

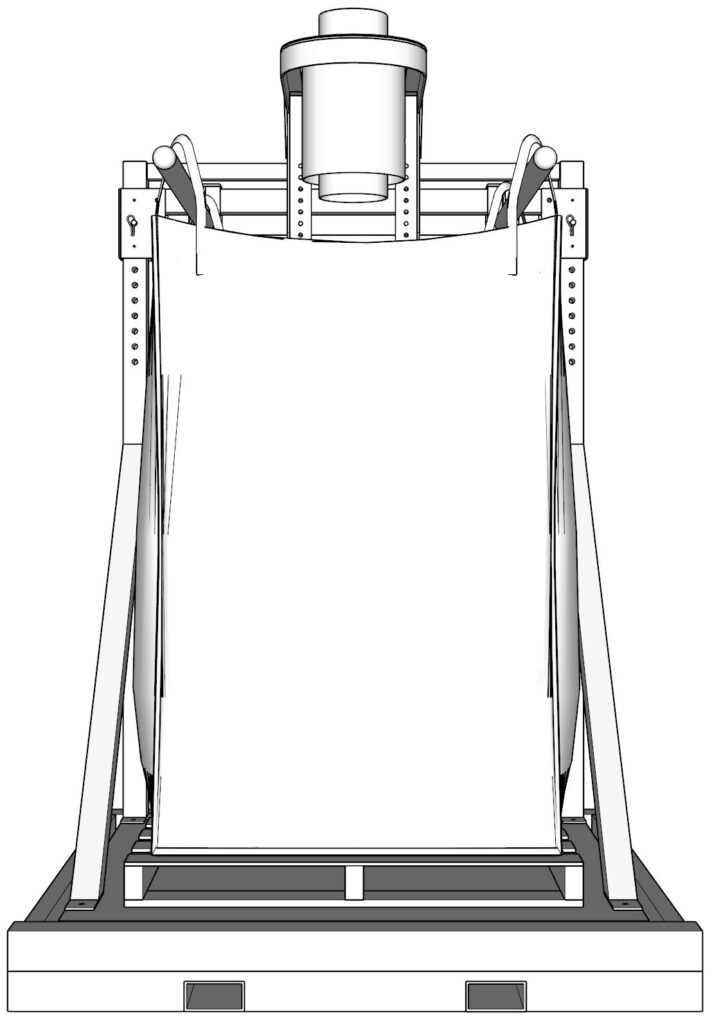

Seamless Inflatable Cuff

The USS ULTRA-BAGGER™ Seamless Inflatable Cuff, manufactured of food-grade neoprene, expands against the inside of the bulk bag fill spout, sealing the opening to guard against product contamination and to control dust. All product contact points are constructed of stainless steel. An internal passage in the product fill spout allows the evacuation of dust during the filling cycle. A remote push button is provided to inflate and deflate the cuff.

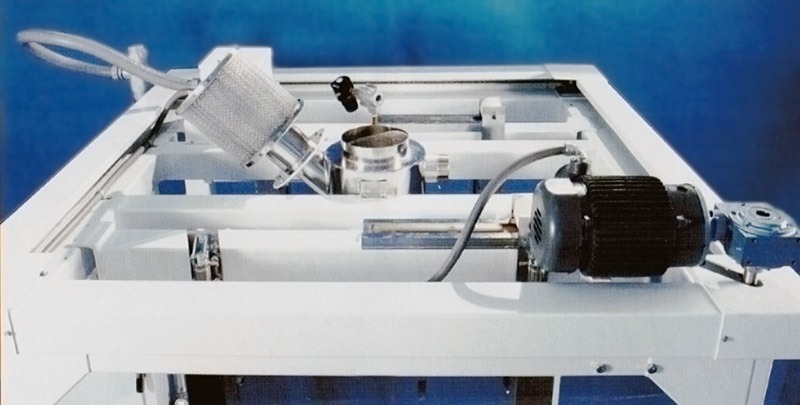

Bag Inflation, Motorized Height Adjustment, Product Valve

A system to inflate the bulk bag before starting the filling cycle is housed within the air intake filter. An exhaust air filter assembly can be added or a connection to your existing dust collection system can be made to capture displaced air from the bulk bag.

The motorized height adjustment includes a motor, a gear reducer, lead screws with bronze nuts in each leg, and chain and sprockets to tie the system together. The upper and lower limits are controlled by a proximity switch.

The product valve to control the flow of your material is attached to your product source. A flexible hose then connects the valve to the bulk bag filling machine.

Why Do Our Customers Love the Ultra-Bagger™ Densifier So Much?

Not all densification methods are created equal. Vibrating a bag may help the material settle but doesn’t cut it for our most demanding customers. High Frequency, Low Amplitude vibration doesn’t PACK material. That’s why our customers prefer the Ultra-Bagger’s™ High Amplitude, Low Frequency densification method.

Densification Magic: High Amplitude, Low Frequency

Our unique patented densifier lifts the bulk bag and drops it downward using the sheer bulk weight to compact material into spaces between particles – pushing air out of the material so it occupies a smaller volume.

We have customers able to stack bulk bags 2-high in the warehouse, effectively doubling the storage capacity of their facilities.

Vibrating a bulk bag or box may help, but it is not as good as “packing” the material using its own momentum from the force of gravity.

What Customers Have to Say About It

One of our customers we have a long relationship with wrote to us:

“With 28 years of experience in the Bulk Bag industry I have found that the low amplitude high impact method of settlement has been one of the best methods for settling bulk bags. Especially when dealing with bags that are palletized. Lift and drop method of settling while the bag is under complete control is superior to most other methods of settling that I have experienced. Vibration of a bag that is on a pallet is dampened to the extent that the actual effect is minimum.”

Another customer who has purchased 9 fill stations over the last 15 years specifies:

“Densifier shall be a “lift and drop design. Simple bag vibration is unacceptable.” This is a large chemical manufacturer who has multiple plants and has tried many solutions, finally to be satisfied with our method.

If densification is an important feature of your filling system give USS a call for a free consultation.

WHEN YOU NEED BULK BAGS PACKED FULL, THERE IS NO COMPETITION WITH OUR PATENTED DENSIFYING SYSTEM.

Field Photos of Installations:

Automation

Our systems feature industrial-duty control panels that automate much of the process, allowing your system to run smoothly, with less downtime.

We build control panels to meet your application needs and may include:

- NEMA-Rated Panels

- Disconnect Switch

- Primary Circuit Protection

- Industrial-Duty Buttons, Selector Switches, and Door Devices

- PLC – Programmable Logic Controller

- Motor Starters

- HMI – Human Machine Interface

- LED Indicator Lights

- Variable-Speed Controls

- Touchscreen

- Remote Networking Capability

- Data Collection

“THE MOST VERSATILE BULK BAGGER ON THE MARKET”

WHAT A USS PORTA-BAGGER™ CAN DO FOR YOU:

FEATURES AND OPTIONS:

- Accommodates up to 67″ FIBC Bulk Bag wall height

- Width-adjustable bag loop guides with rounded ends

- Food-grade flexible product sleeve for vertical adjustment

- Forklift tine-slots for portability

- Stainless steel product spout with an inflatable cuff

- Easy-reach hand-actuated air valve for inflatable cuff

- Floor scale load cells

- Integrated weight indicator

- Slide-gate valve with dribble function

- Flared legs for stability

- 60 degree slope for easy product flow

- Vibrator mounts for product flow

- Surge bin filter receiver with pulse-jet technology

- Easy access door with tooless entry

- Bag inflation fan for quick filling

- Stainless steel food-grade product contact areas

- Bag filling dust filter for dusty or hazardous materials

- Motorized height adjust

- Densification

BENEFITS:

- Use a wide variety of bulk bags

- Can be paired with a USS SKIDPOT™ portable pneumatic conveyor

- Durable design for decades of use

- Dribble function for accurate weighing

- Product flows easily

- Safe for operators to use

- Long-lasting industrial-duty components

- Can be used at one location or different sites

- Pay only for the options you need

- Capital investment moves where you need it most

- Densification option optimizes bag utilization

- Motorized height adjust makes changing bag size a breeze

- Easy removal of filtration media

- Easy to ship

- Easy to use

- Easy to move

- Easy to clean

- Easy to maintain