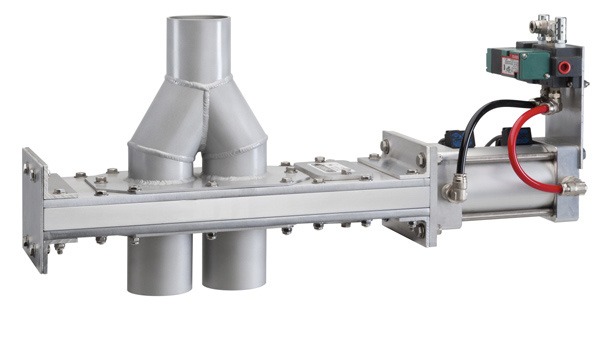

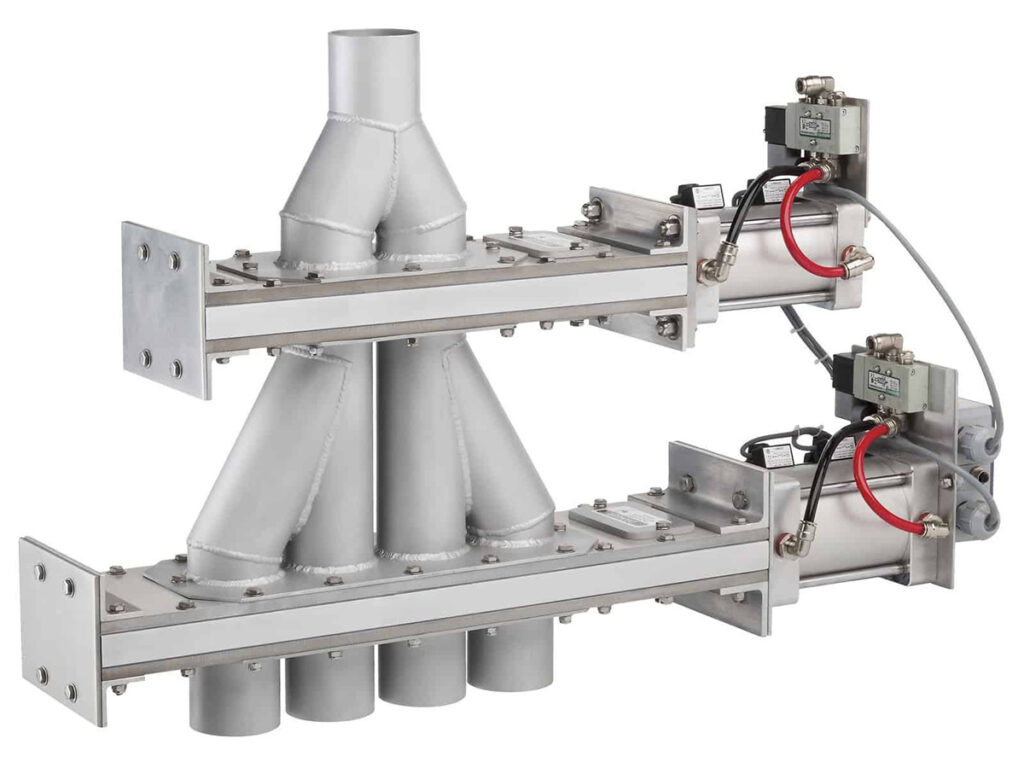

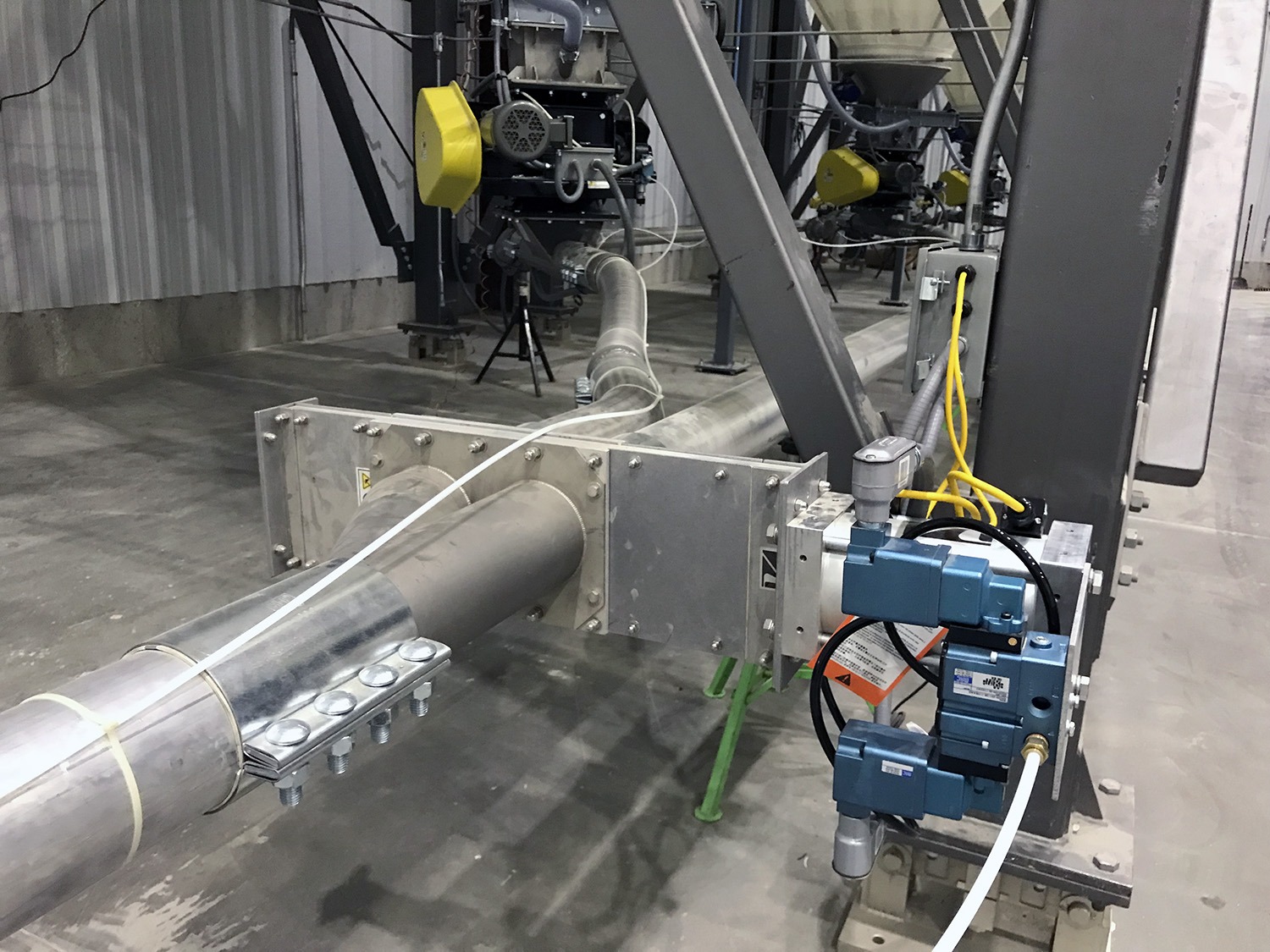

Diverter Valves

The Pneumatic Conveying Diverter Valve is used to reroute product from one convey line to another.

Construction Material: The body is available in cast iron, cast aluminum or cast stainless steel.

An internal flap plate is fabricated of mild steel or stainless steel, with a polyurethane rubber wiper seal.

To order: please specify the size and number of inlet and outlets, the material of the internal flap, and the construction material.

If you have any questions regarding the specifications that apply best to your application please call or send us a message and we’ll help you select the best valve.