Butterfly Valve

Butterfly valves are used in pneumatic conveying applications for shutting off and regulating the flow of air and material.

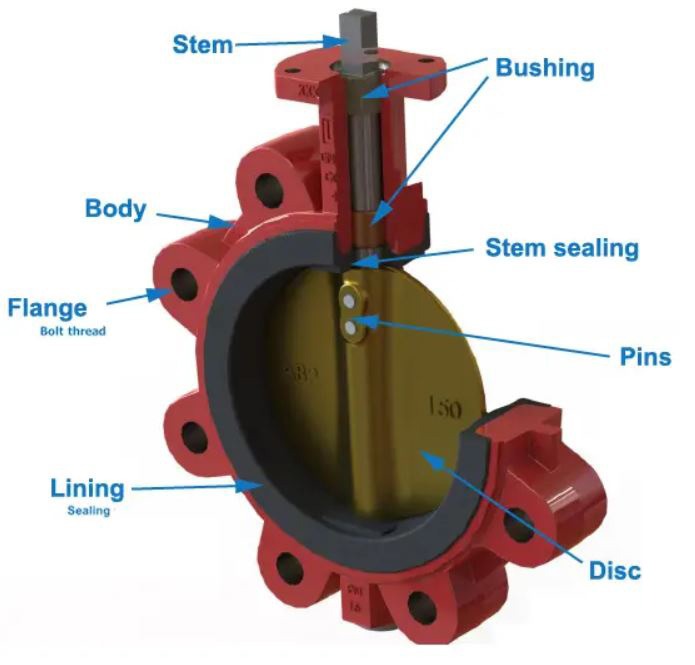

Butterfly valves are a family of valves called quarter-turn valves that feature a rotating disc (the “butterfly”) fixed to a valve stem.

The entire valve is made up of a valve body, disc, stem, seat, and use handles, gears, or automatic actuators for operation.

The internal disc pivots on a center axis when the valve stem is turned, allowing 90° of movement – fully open or closed.

- 2″ to 12″

- Wafer Style

- Lug Style

- Cartridge Seat

- Thin Profile Disc

- ISO mounting and Shaft

- Rated to 50 psi, 200 psi, 285 psi

- Vacuum Rated to 29.92” of Mercury Gauge

To order: please specify the diameter, body type (SS or Carbon Steel), connection type (wafer, lug, semi-lug), and seat material (Viton – heat rated or Buna N – non-heat-rated).

Functions of a Butterfly Valve

The main functions of a butterfly valve are:

- Flow regulation: Flow can be easily controlled or regulated simply by turning the valve wheel or by pneumatic actuation.

- Flow Isolation

- Prevention of Backflow: Butterfly valves can be used for backflow prevention in some situations.

More information about our butterfly valves:

- The One-piece ribbed wafer and lugged body is polyester coated as standard, for a superior appearance and excellent resistance to external corrosion.

- Heavy duty ISO 5211 top plate is slotted for ease of actuation and engineered to accept direct mounting of operators.

- Streamlined design offers higher Cv and lower pressure drop.

- Triple shaft seals support the primary seal on the machined radius of the disc. Our triple shaft seals ensure a dry stem design.

- Field replaceable, phenolic bonded cartridge seat provides no movement of the elastomer, which is a common failure point of many resilient flexible seat designs.

- Torque fluctuation is eliminated by our phenolic-bonded elastomer seats.

- A high-strength Double D drive ensures a positive shaft-to-disc connection.

- No pins or bolts are exposed to flow.

- Disc shaft holes, surrounded by a 360° machined radius, are in constant contact with the flatted area of the seat.

- The design is far superior to resilient flexible seat designs that depend on the “squeeze” effect of the disc and seat interference, which allows leakage behind the seat and up the shaft.

- The shaft seal is achieved through continuous pressure exerted from the flatted area of the seat to the machined radius of the disc.