Truck Loading/Unloading

Faster Rates – Less Downtime – Superior Dust Control

No Pneumatic Truck? NO PROBLEM.

PNEUMATIC TRUCKS ARE EXPENSIVE.

USE A USS HOP-VAC™ ADAPTER WITH CHEAPER COVERED HOPPER TRUCKS INSTEAD.

Our customers call on us to solve all kinds of problems. We’ve listened and have a new solution to help our customers save tons of money while moving tons of material…fast.

We’ve made it EASY to pneumatically convey dry bulk material from a hopper truck to your plant or silo with NO NEED FOR A PNEUMATIC TRUCK TRAILER!

HOW IT WORKS

Four simple steps to unload a hopper with the vacuum adapter:

-

- Roll it under the hopper gate and lock the wheels.

- Attach the 22oz heavy-duty vinyl around the hopper to control spillage and dust.

- Connect the hose.

- Press “start” on your pneumatic conveyor and unload the hopper.

FEATURES & BENEFITS

- Industrial-duty construction with aluminum product contact areas with painted carbon steel legs and handle.

- Heavy-duty locking castors make positioning and securing the adapter a breeze.

- Telescoping legs to accommodate various hopper heights.

- Operators love the extended handle for easy movement.

- Heavy-duty flexible 22oz Vinyl Coated Polyester dust shroud prevents material from falling or blowing out.

- Ball-valve or blast gate allows the operator to adjust the material-to-air ratio for maximum output without plugging.

- Line cleanout port included for material inducement.

Ask us about using a USS Hop-Vac™ Adapter with a USS Skidpot™ and save a ton of money while conveying tons of material.

The USS SKIDPOT™ on the left side of the screen vacuums material through the HOP-VAC™ Adapter, sweeping it into the “pot”.

The system then switches modes to pressure and the pot pressurizes sending the material to the silo. The cycle continues until the hopper is empty.

This truck is carrying an ingredient for a fish food manufacturer. Both hoppers were unloaded in under 2 hours with no mess, spillage, contamination, or fuss.

Trucks. They transport a massive amount of dry bulk material across the world and we’re here to help transport material in and out of the trucks themselves.

There are many advantages to pneumatic truck unloading compared to mechanical conveying. Less moving parts means less breakdowns, and an enclosed system means easy dust control. Another important advantage is flexibility in routing – we can convey material to places others can’t.

Our Pneumatic Conveying Solution Eliminates:

- Blow-by Air

- Worn Shaft Seals

- Bent Rotors

- Holes in Elbows

- Wasted Horsepower and Energy

- Worn Out Housings

- Chain Drive Maintenance

- Valves with Inherent Leaks

High Rate Trailer Unloading

These high-rate systems employ either diesel or electric-driven units that can range from 10 to 200 horsepower and can move material at a rate of one to one-hundred tons per hour.

We Achieve High Rates with All Types of Truck Trailers:

- Hopper

- Dump

- Pressure Differential Pneumatic Trailers

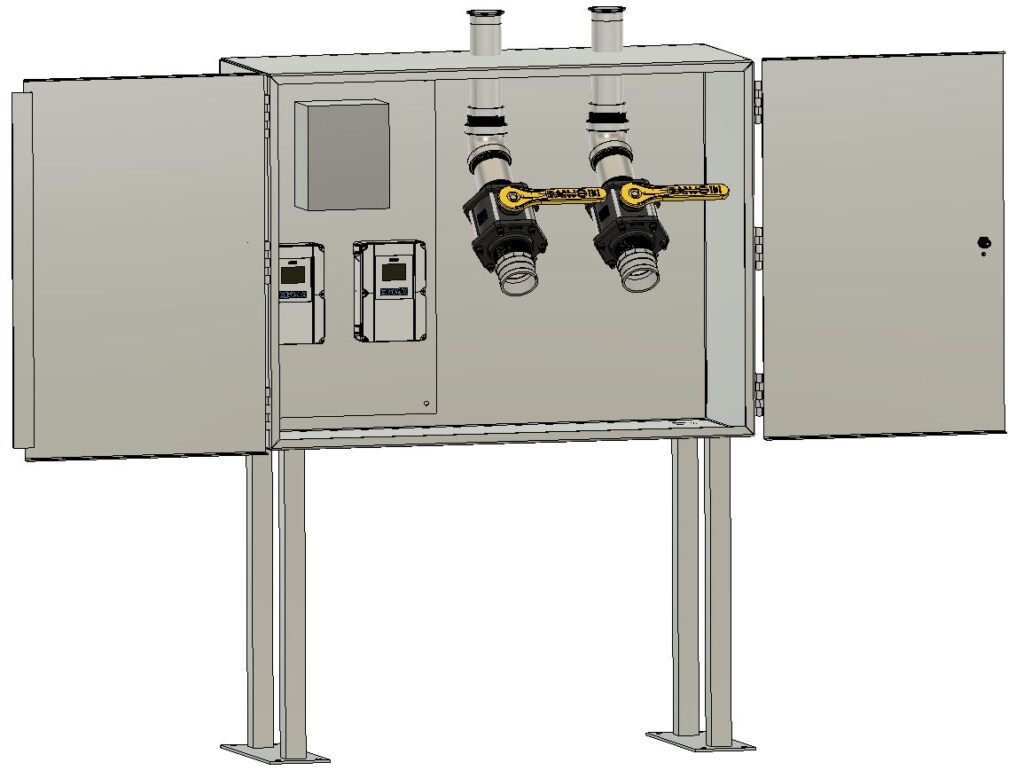

We Provide Choices:

Depending on the application, proven solutions could include header systems for multiple trucks, choices of vacuum, pressure, or combination systems and portable and self-powered units.

Other Options Include:

- Booster for Multiple Trailers

- Choices of Vacuum, Pressure, or Combination Systems

- Portable and Self-Powered Units