The most important consideration in the design and implementation of a bulk material vessel is the material itself. Every material has different properties of cohesion that are considered and a solution applied that allows for the best flow possible. We get it right the first time, saving you time, money, and aspirin.

A poorly-designed hopper can cause a lot of problems and headaches that no one has the time to deal with. Through scientific evaluation and best-practice design principles we will get it right the first time – ensuring that your material flows as it should so you can move on to more pressing concerns.

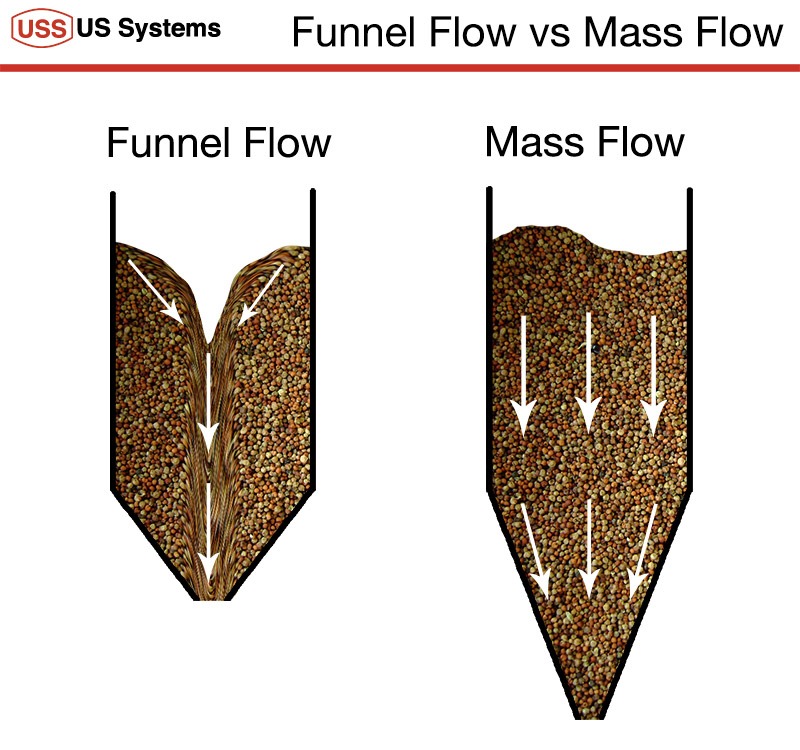

Funnel Flow vs. Mass Flow

Two important concepts in bin design is Funnel Flow and Mass Flow.

Funnel Flow

In funnel flow, material flows downward by gravity in the middle of the bin with stagnant material remaining along the wall of the vessel. Funnel flow can be advantageous when headroom is at a premium and the application is not depending on FIFO (First-In-First-Out) sequence or uniform flow.

Funnel flow in a bin that doesn’t completely discharge can limit the capacity of the tank, as material left in the tank reduces ‘live’ capacity. It can also segregate fines and dust, keeping your material from uniformly flowing into the next stage of your process.

In worst-case scenarios, your material will be erratic or stop altogether, and you end up with idle equipment that can cause delays in shipping your product.

In many applications funnel flow isn’t a problem, and depends on the material and process. If funnel flow produces undesirable effects then Mass Flow may be the answer to the problem.

Mass Flow

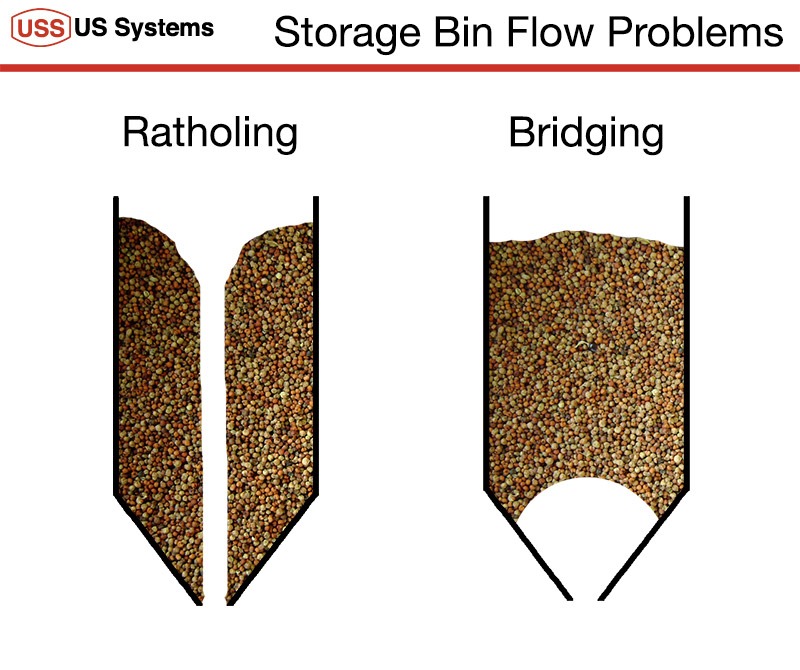

Mass flow may be necessary to ensure your process runs smoothly, or to ensure FIFO sequence discharge. To create mass flow (uniform flow of material), bin and cone geometry is the first factor taken into consideration. We design mass flow hoppers to avoid bridging, rat-holing, and other problems by optimizing the ratio between material height to bin width.

Depending on the material and application we may also employ industrial-duty cone treatments such as aeration or vibration pads to keep the material flowing smoothly. Internal baffling can solve certain flow issues as well. These must also be applied with great care, as misapplication of cone treatments can cause problems as well.

US Systems Solves Flow Problems:

Use bins, surge hoppers, day bins, scale hoppers, storage bins, batch bins, tanks, vessels and silos are important but humble pieces of process equipment. They absolutely need to run reliably or an entire process line can sit idle.

We have the experience and expertise to analyze your needs, and design a safe, reliable system that avoids many of the problems we’ve seen in systems designed by others.

Our philosophy is that form follows function. The first question is, “What does this particular part of the process need to do?”. Then we design your system around that question to create the most cost-effective, least maintenance, reliable option.

When it comes to our storage, batching, and scaling systems, we:

- First and foremost build safe structures to prevent injury and equipment damage

- Produce reliable flow by avoiding bridging and ratholing

- Apply cone treatments to work reliably and avoiding problems

- Ensure proper ventilation where needed to avoid dust issues

- Take into consideration material build-up and bin cleaning

- Avoid condensation, that can ruin material and impede flow

- Build systems with user-friendly access points

- Eliminate dead spots with muliple outlets

Field Photos of USS Silos

US Systems Pneumatic Truck

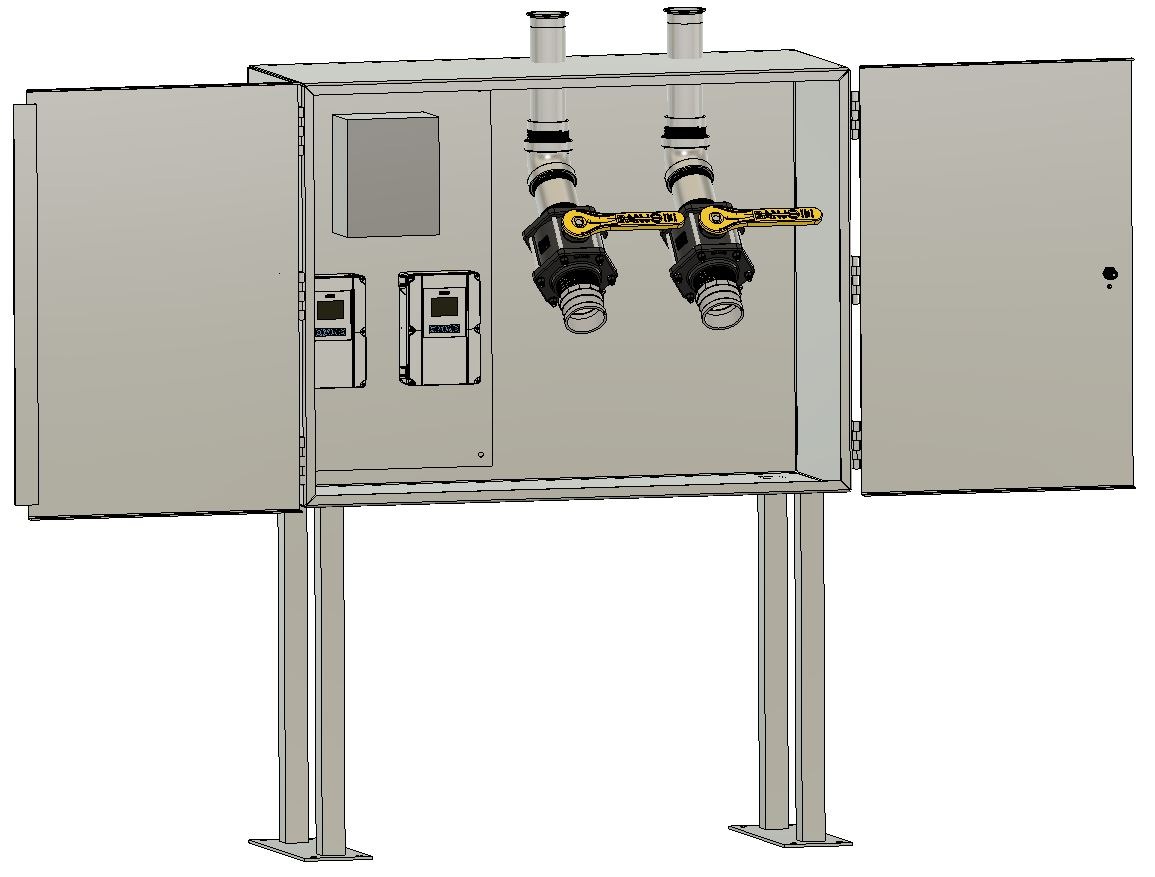

Receiving Inlet Panel for Silos

Connection between the delivery vehicle and the silo or plant system is most often made through an Inlet Panel, sized according to the system requirements.

The unit is comprised of a stainless-steel or painted carbon steel sheet metal enclosure fitted with a key-locked door if security is desired. Contains one or more stub tubes for product receiving fitted with a quick-connector, valve, and dust cap.

Security, cleanliness, and ease of operation make this panel especially ideal for food and pharmaceutical applications, among others. Protect your inlet from the elements and protect access to your plant with a locking inlet panel.

Features/Options/Benefits:

- Stub Tube Assembly with valve; specify size and quantity

- Start/Stop Buttons

- Indicator Lights

- Visual and Audible High-Level Alarms w/Alarm Reset Button

- A NEMA 4 Control Connection Panel Housed within Inlet Panel can communicate with your PLC to control the Bin Vent Pulse Jet system and/or anything else.

- Header with Connection to Dry Air for the silo available as an option

- Can be utilized with railcar unloading as well

- Have a unique need? Great! We custom-design our inlet panel for each application. Just tell us what you require.

- Easy to customize

- Easy to install

- Easy to use

- Easy to maintain